Adept Cobra s350 User’s Guide, Rev. A

63

System Operation

6

6.1

Using the Brake Release Button

Brakes

The robot has a braking system which decelerates the robot in an emergency condition,

such as when the emergency stop circuit is open or a robot joint passes its softstop.

Instructions on configuring the Programmable E-Stop delay can be found within the SPEC

section of the

Instructions for Adept Utility Programs

manual. The default setting is

correct for most applications.

The braking system will not prevent you from moving the robot manually once the robot

has stopped (and High Power has been removed).

In addition, Joints 3 and 4 have electromechanical brakes. The brakes are released when

High Power is enabled. When High Power is turned off, the brakes engage and hold the

positions of Joints 3 and 4. There is a Brake Release button for Joints 3 and 4 on the

MB-40R and a Brake Release button on the robot itself. See

for information on the Brake Release button on the MB-40R.

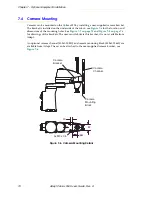

Brake Release Button on Robot

Under some circumstances you may want to manually position Joint 3 or Joint 4. For such

instances, a Brake Release button is provided. When system power is on, pressing this

button releases the brake, which allows movement of Joint 3 and Joint 4.

Figure 6-1. Brake Release Button for Third and Fourth Axes

Summary of Contents for Cobra s350

Page 1: ...Adept Cobra s350 Robot User s Guide...

Page 2: ......

Page 16: ...Chapter 1 Introduction 16 Adept Cobra s350 User s Guide Rev A...

Page 34: ...Chapter 3 Robot Installation 34 Adept Cobra s350 User s Guide Rev A...

Page 50: ...Chapter 4 MotionBlox 40R 50 Adept Cobra s350 User s Guide Rev A...

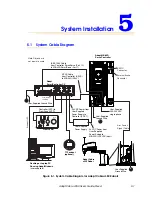

Page 62: ...Chapter 5 System Installation 62 Adept Cobra s350 User s Guide Rev A...

Page 66: ...Chapter 6 System Operation 66 Adept Cobra s350 User s Guide Rev A...

Page 84: ...Chapter 8 Maintenance 84 Adept Cobra s350 User s Guide Rev A...

Page 90: ...Chapter 9 Technical Specifications 90 Adept Cobra s350 User s Guide Rev A...

Page 98: ...Chapter 10 Cleanroom Robots 98 Adept Cobra s350 Robot User s Guide Rev A...

Page 102: ...Index 102 Adept Cobra s350 User s Guide Rev A...

Page 103: ......

Page 104: ...3011 Triad Drive Livermore CA 94551 925 245 3400 P N 05624 000 Rev A...