Installation and Commissioning Guide - Package Commercial Unit

Doc. Part No. 0525-055 Ver. 9 220308

Installation and Commissioning Guide

Package Commercial Unit

16

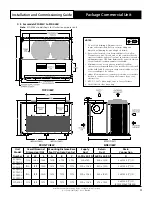

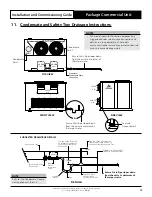

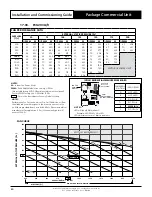

Cluster Configuration

COMP

COMP

COMP

Unit 2

Service

Clearance

(Comp. and

Electricals

+

Fan)

Unit 3

Airflow

Clearance

Duct

Work

Duct

Work

UNIT 1

OUTD

O

OR C

OIL

OUTDOOR COIL

IND

O

OR C

OIL

FA

N

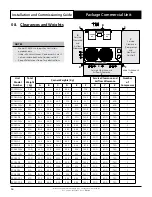

Airflow Allowance

C

OMP

B

Service Clearances

(Compressor and Elect Fan)

Duct

Work

Duct

Work

UNIT 2

OUTDOOR COIL

OUTD

O

OR C

OIL

INDOOR COIL

FAN

A

C

Airflow

Allowance

COMP

A

Duct

Work

Duct

Work

UNIT 3

OUTD

O

OR C

OIL

OUTDOOR COIL

IND

O

OR C

OIL

FA

N

Airflow Allowance

C

OMP

Service Clearances

(Compressor and Elect Fan)

B

A

D

B

C

A

ir

flo

w A

llo

wance

C

A

ir

flo

w A

llo

wance

D

D

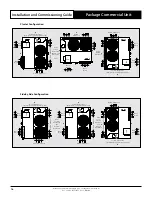

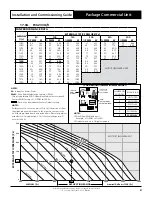

Side By Side Configuration

COMP

COMP

COMP

Unit

2 or 3

Service

Clearance

and

Airflow

Allowance

OUTD

O

OR C

OIL

Duct

Work

Duct

Work

UNIT 3

OUTDOOR COIL

IND

O

OR C

OIL

FA

N

Airflow Allowance

C

OMP

Service Clearances

(Compressor and Elect Fan)

B

A

C

A

ir

flo

w A

llo

wance

Unit 1

Service

Clearance

and

Airflow

Allowance

Duct

Work

Duct

Work

UNIT 1

OUTD

O

OR C

OIL

OUTDOOR COIL

IND

O

OR C

OIL

FA

N

Airflow Allowance

C

OMP

B

Service Clearances

(Compressor and Elect Fan)

A

C

A

ir

flo

w A

llo

wance

Duct

Work

Duct

Work

UNIT 2

OUTD

O

OR C

OIL

OUTDOOR COIL

IND

O

OR C

OIL

FA

N

Airflow Allowance

C

OMP

B

Service Clearances

(Compressor and Elect Fan)

A

C

A

ir

flo

w A

llo

wance

D

D

D