Wire Rope Hoist

PAGE: 44

Model WR

WR-0214

2721 NE 4

th

Ave Pompano FL, 33064 | (954) 367-6116

Visit WWW.ACIHOIST.COM for the most current information

To correct trolley motor phasing:

c.

Interchange any two lines supplying power to the trolley motor only. DO NOT reverse main power leads to the

hoist as this will also effect the phasing of the hoist motor.

d.

Re-energize power supply to the hoist.

e.

Re-check trolley travel for correct trolley motion. If direction of trolley travel agrees with the direction marking of

the trolley control device activated (i.e., trolley direction is LEFT when the trolley LEFT control device is

activated), trolley motor is properly phased. If the direction of trolley travel does not agree with the direction

marking of the trolley control device activated (i.e., trolley direction is RIGHT when the trolley LEFT control device

is activated), trolley motor is improperly phased and must be corrected by repeating steps a through e.

Operate hoist in the raising and lowering direction, without load on the hook, and stop motion to check operation of the

motor brake. The drift of the hook should not exceed one inch in either direction. If hook drift exceeds one inch, the

motor brake requires adjustment. Refer to the MOTOR BRAKE section of this manual for instructions on motor brake

adjustment.

Check operation of limit switches as follows:

a.

All checking of limit switches should be accomplished without a load on the hook. All checking of limit switches

should be accomplished by using the low speed of multiple-speed hoists, or inched into the limit if the hoist is a

single-speed unit.

b.

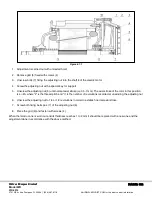

Hoists with the standard gravity type upper limit switch:

Check the gravity type upper limit switch by operating the hoist in the lifting direction. While the load block is

raising, lift the weight of the upper gravity type limit switch manually until motion of the load block stops.

Lifting the weight higher should cause the load block to lower until the weight is released. If raising motion

does not stop when the weight is lifted, STOP hoist motion as the upper gravity limit switch requires

adjustment or replacement. The lowering motion achieved by lifting the weight after raising motion of the

load block has stopped is a reverse plugging feature to minimize the possibility of the load block striking the

hoist frame or drum if the motor brake is out of adjustment. If adjustment of the gravity type upper limit

switch is required, refer to the LIMIT SWITCHES section of this manual.

Operate hoist in the lifting direction to a point where the block is about 12 inches below the hoist drum. If the

hoist has more than one speed, continue to raise at low speed or; if hoist is a single-speed unit, inch the load

block in the lifting direction until motion of the load block stops to check that load block stops when

Striking the weight of the gravity upper limit switch before striking any other part of the hoist. If the load block

will hit any part of the hoist prior to striking the weight of the gravity type limit switch, STOP hoist motion as

a.

Disconnect power and lockout disconnecting means before reconnecting (reversing) power

lines to trolley.

b.

Only a qualified electrician should reconnect the power lines to the trolley.

Disconnect power and lockout disconnecting means before adjusting limit switches. Limit switches

should be adjusted using a continuity tester or other type of tester that will indicate open or closed

circuits without the need of electrical power.

Only a qualified electrician should adjust switches.