Wire Rope Hoist

PAGE: 20

Model WR

WR-0214

2721 NE 4

th

Ave Pompano FL, 33064 | (954) 367-6116

Visit WWW.ACIHOIST.COM for the most current information

Check power supply that will be furnished to the hoist and trolley. It must be the same as shown on the hoist and

trolley serial plate.

Check wire rope for damage and spooling on drum. Be sure rope is properly seated in drum grooves and

sheaves. Make sure both of rope ends are tightly secured.

After each rope replacement as well as after repair and reassembling of the electric hoist check the phasing and

the limit switch adjustment for upper and lower position of the loading hook.

While carrying maintenance and repair activities for electric repairs/maintenance, make sure that there is no load

on the hook; the power supply switch is turned off and unauthorized switching on is eliminated.

Check the loading hook for cracks and deformations as well as the good working order of the fuse for self-

release of the load.

Check the bearing screw joints to avoid them eventually self-unwind.

Check the reliable connection of cable protective conductors to the grounding terminals in the electric board as

well as the transformer and the electric.

If hoist has a trolley, check that the crane bridge beam or monorail beam is level, straight, and clean. Check that

trolley stops are installed, or install trolley stops, at the open end or ends of the beam to prevent the trolley from

traveling off the beam. Trolley stops that engage trolley wheels are not recommended. Check that trolley stops

will prevent overhanging parts of the hoist and trolley from interfering with other equipment beyond the ends of

the beam or monorail.

4.2 Installation of Hoist

Fixing the Rope

Depending on the size of the electric hoist and the conditions of packing, the hook-block may be delivered disassembled

from the rope. After installing the hook-block, the rope must be tight and shouldn’t be twisted. Fix the rope ends as in the

following order:

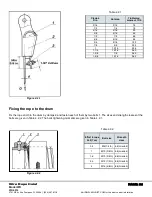

Fixing the rope end to the body (See Figure 4.2.1)

Fix the rope of diameter “d” in the wedge bush 2, so that its bearing section would lie on the vertical side of the wedge 1.

To secure the rope ends from falling out, a clamping element 3 is mounted by nuts at the end of the rope.

The distance between the rope end and the wedge bush 2 shall be at least 3.9 inches the maximum distance is:

9.8 inches for 0.5 and 1 ton hoist capacity

13.8 inches for 2, 3, 4 and 5 ton hoist capacity

17.7 inches for 8 ton hoist capacity

The distance between the clamp 3 and the rope end shall be 1.97 inches.

The main switch (disconnect) supplying power to the crane, monorail, or other piece of

equipment where the hoist is to be installed, shall be de-energized. Lock and tag the main

switch in the de-energized position in accordance with ANSI

Z244.1.