Wire Rope Hoist

PAGE: 29

Model WR

WR-0214

2721 NE 4

th

Ave Pompano FL, 33064 | (954) 367-6116

Visit WWW.ACIHOIST.COM for the most current information

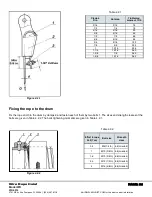

4.8.2 Adjusting the lever system actuating the end limit switch

If during operation adjustment of the emergency end limit switch is needed, it may be effected by changing the location

of the limiting rackets 1 and 3 on the bar 2 (fig.4.8.1.1). The limiting racket 1, located from the side of the electric motor,

adjusts the distance between the floor and the lowest point of the load hook - lower end position. The limiting racket 3

adjusts the distance between the lowest point of the hoist and the roller block - upper end position.

After adjusting the two limiting rackets fasten the bolts 4 and secure them by with cotter pins 5.

Checking the adjustments:

For upper end position of the hook-block:

The unloaded hook shall move upwards until the end limit switch actuates. In this case maximum brake

path is realized.

For lower end position of the hook-block:

The unloaded hook shall move downwards until the end limit switch actuates. In this case maximum brake path

is realized.

The second stage of the end limit switch is of emergency function and switches off the main contractor. In this case:

The distance between the lowest point of electric hoist and the highest point of the roller block should be at least

3.9 inches.

The distance between the floor and the lowest point of the hook shall be at least 3.9 inches and there must be at

least 3 full winding of the rope on the drum.

4.8.3 Checking the Lubrication of the Electric Hoist

ACI Wire rope hoists are lubricated and tested before being shipped from factory. Type, specifications and quantity of the

lubricants are given in Table 6.6.2. Before operating the hoist, it's necessary to check the lubrication of the hoist and if

needed grease the points, shown in the lubrication scheme - Table 6.6.1.

4.8.4 Hoist Load Test

Complete hoists are load tested by ACI in accordance with ASME B30.16. Exceptions to this procedure could

occur if special design features of the hoist do not permit it to be placed in the ACI hoist load test stand. In such

cases, the purchaser shall be notified of this fact, and it is the responsibility of the owner/user to load test the

hoist in accordance with ASME B30.16.

Hoists furnished in an uncompleted condition (i.e. less controls, less motor, less wire rope, etc.) as hoist

components, and winch units are not load tested by ACI. Therefore, it is the responsibility of the owner/user to

load test the final lifting system using such hoist components or winches in accordance with ASME B30.16.

If the hoist is installed on a crane, load testing of the crane in accordance with, as applicable, ASME B30.2,

ASME B30.11, or ASME B30.17 may be required.

If a load test in accordance with one of the B30 Standards is not required, the hoist should still be operated with

a load on the hoist hook prior to being released for operating purposes.

o

Attach a load to the hoist hook. Load shall not exceed the rated load capacity of the hoist.

o

Before lifting the load, operate the hoist in the raising direction to take any slack out of the hoist wire

rope.

o

Raise the load a few inches and stop the hoist. If brakes stop and hold the load, continue raising and

lowering the load several feet, stopping the hoist several times in each direction to check that the hoist

braking system stops and holds the load.