35

6.8 FUNCTION OF THE SAFETY SYSTEM

The safety system can be triggered (E-stopped) by any one of four separate devices. These devices are the

Light Curtain, E-stop Button, Home Brake Beam and the Away Brake Beam. The E-stop Button and Light

Curtain are two channel devices meaning that two separate electrical paths are monitored in each.

Breaking the flow of current in either path will cause an E-stop condition to occur. A broken wire or other

failed component in either path will also cause an E-stop. An E-stop condition causes power to be removed

from the air system dump valve and servo amp inputs as well as the Infeed deck motors to stop the

system.

The Brake Beam sensors supply power to Inputs 165 and 166 causing the control system to output power

on Output 202. The current to power the Light Curtain originates from Output 202 and passes through

both channels of this device and the E-stop Button to power the Safety Relay inputs. Breaking either of the

Brake Beams or the Light Curtain beam or pushing the E-stop Button will cause the Safety Relay to open

dumping the system air supply and shutting down the Gantry and Infeed Deck motors. Breaking any of the

Beams will require a special reset procedure which is different from the reset procedure required when

pushing the E-stop button. See section 6 .

The status of the overall Safety System can be viewed on the Main screen on the PC. Here you can view

the actual inputs from each of the safety devices and the reset status of the Safety relay. The cause of the

last E-stop can be viewed here even if it was an intermittent problem. This is explained in the next section.

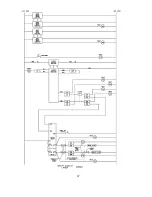

Shown here is a diagram of the Wood Runner safety system. The main components and the

interconnections between them and the system PC are detailed.

This is not meant to be a wiring diagram;

it is designed to show the theory only

. The diagram shows the dual path that must be maintained through

the various safety input devices and the inputs from the devices to the system PC.

Summary of Contents for Wood Runner

Page 5: ...5 ...

Page 36: ...36 ...

Page 37: ...37 ...

Page 54: ...54 ...

Page 55: ...55 10 DETAILED PARTS IDENTIFICATION WOOD RUNNER 10 1 RUNWAY ASSEMBLY ...

Page 58: ...58 10 3 RUNWAY DRIVE ASSEMBLY ...

Page 61: ...61 10 5 GANTRY ASSEMBLY ...

Page 62: ...62 GANTRY ASSEMBLY ...

Page 64: ...64 10 6 PICKING HEAD ASSEMBLY ...

Page 65: ...65 PICKING HEAD ASSEMBLY ...

Page 68: ...68 10 7 ELECTRICAL PANEL ASSEMBLY ...

Page 70: ...70 10 8 GANTRY ENCLOSURE ASSEMBLY ...

Page 72: ...72 10 9 CONSOLE ASSEMBLY ...

Page 73: ...73 CONSOLE ASSEMBLY ...

Page 75: ...75 10 10 AIR SUPPLY ASSEMBLY ...

Page 77: ...77 10 11 GANTRY VALVE ASSEMBLY ...

Page 79: ...79 10 12 GANTRY BRAKE ASSEMBLY ...

Page 81: ...81 11 ELECTRICAL DIAGRAMS 11 1 SYSTEM OVERVIEW ...

Page 82: ...82 11 2 MAIN ENCLOSURE LOW VOLTAGE ...

Page 83: ...83 11 3 GANTRY WIRING LOW VOLTAGE ...

Page 84: ...84 11 4 I O CHART ...

Page 85: ...85 11 5 INFEED WIRING LOW VOLTAGE ...

Page 86: ...86 11 6 OPERATORS CONSOLE ...

Page 87: ...87 11 7 MAIN ENCLOSURE HIGH VOLTAGE ...

Page 88: ...88 11 8 MAIN ENCLOSURE RECEPTACLE WIRING ...

Page 89: ...89 11 9 SAFETY CIRCUIT LAYOUT ...

Page 90: ...90 11 10 SAFETY CIRCUIT DIAGRAM ...

Page 91: ...91 11 11 BRAKE SENSOR DIAGNOSIS ...

Page 92: ...92 12 PNEUMATIC DIAGRAMS 12 1 SINGLE HEAD GANTRY ...

Page 93: ...93 12 2 DOUBLE HEAD GANTRY ...

Page 94: ...94 12 3 INFEED DECK ...