AXS

–

Ramp Manual

AXS FL RAMP Manual rev 1

3

3

Safety instructions

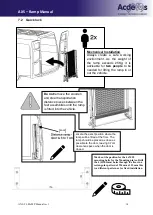

These Safety instructions should always be with the ramp. The operator has to

be made aware of these instructions before operating the ramp. Read these

safety instructions carefully and act on them.

The ramp is constructed as a boarding device for passengers in a wheelchair. It should be used

accordingly by passengers and assisting persons, as long as they are not heavier than the maximum

load, to enter or exit a minibus, van, taxi or other vehicle.

1.

Before you can operate the ramp the Vehicle must be stopped and the hand or park brake

applied.

2.

Make sure it is safe to load or unload your passengers.

3.

Before operating the ramp, make sure that there neither anyone nor any obstacle at or

near to the ramp. Also ensure that there is neither anyone nor any obstacle outside the

vehicle or in the path of the ramp when in motion.

4.

It is recommended that the ramp is operated by the driver only or other qualified

operators.

5.

The driver or operator must have a clear view of the ramp when maneuvering the ramp.

6.

Wheelchair passengers should always be assisted while boarding or un-boarding the

vehicle.

7.

The ramp platform must be kept clean and free of oil and other slippery materials.

8.

If you have any questions about the safe operation of the ramp, contact the person

responsible immediately.

9.

Never use the ramp for any other use than as described above.

10.

Never overload the ramp.

11.

The ramp should be used when it is completely unfolded and firm on the ground.

12.

Repair and maintenance must to be carried out by qualified and trained staff only.

13.

In case of exchanged parts

–

only the original parts of the ramp must be used.

14.

Always use the recommended cleaning materials.

15.

Report any unsafe conditions of the ramp or problems during operation to the ramp

supplier.