23

For more cool Wattage products visit our website at http://watt-age.globalhobby.com

❑

Using a pencil, place a mark on the pushrod wire where it crosses the

middle

hole in the control horn.

WARNING

When making the mark on the pushrod it's important that the rudder and the rudder servo are centered. If they aren't your

pushrod will not be the correct length.

❑

Using needle nose pliers, carefully make a 90º bend in the pushrod wire at the mark you drew.

IMPORTANT

Make the bend up toward the top of the fuselage.

❑

Cut off the excess wire, leaving about 5/16" beyond the

bend.

❑

Insert the wire (from the bottom of the control horn) into

the

middle

hole in the control horn. The tension will keep

the wire in place.

Step 4: Adjusting the Rudder Pushrod

❑

Remove the masking tape from the rudder.

❑

With your radio system plugged in and turned on, check to make sure the rudder and the rudder servo are centered.

Use the trim lever on the transmitter to center the rudder, if necessary. Double check that the rudder is moving in the

proper direction.

❑

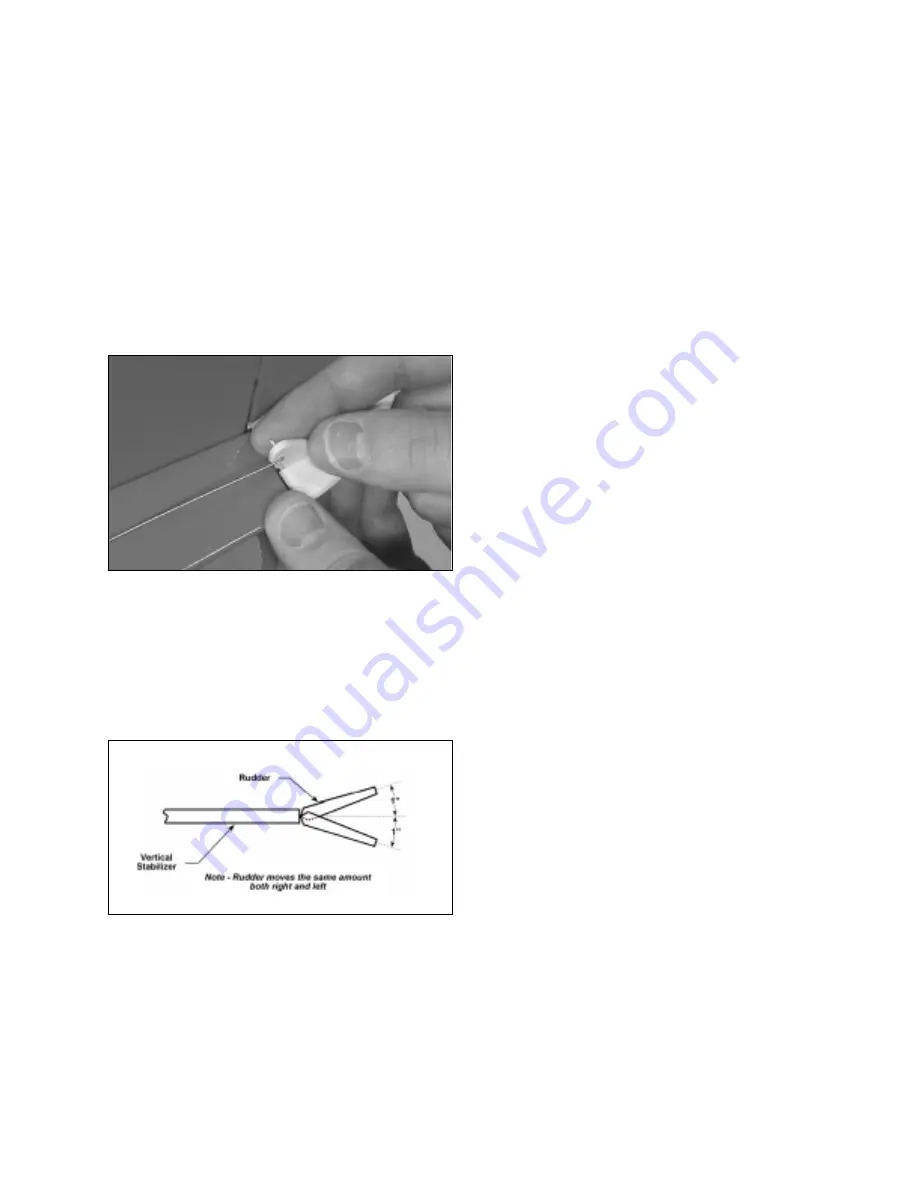

Check the control surface throw by measuring from the

widest point of the control surface. The rudder should move

both right and left 1".

A NOTE TO THE MODELER:

During extensive testing we have not had one pushrod wire come out of a control horn using the technique described. It's

important to leave at least 5/16" of wire beyond the 90º bend. It's also important that the bend be made so that the natural

tension of the wire holds it against the control horn.

If you are uncomfortable with this arrangement you can carefully bend the wire (beyond the control horn) forward.