24

1ZSE 5492-118 en, Rev. 4

4. Drying

A drying agent is placed inside the package to keep the on-load tap-changer dry during

transport. It is not necessary to dry the tap-changer if the package not have been destroyed.

The on-load tap-changer can be dried together with the transformer according to one of the

following processes: alternating hot-air and vacuum or vapour-phase at a temperature of

max. 135 °C (275 °F) and a maximum pressure difference of 100 kPa between tap-changer

and transformer.

4.1 Observations before processing

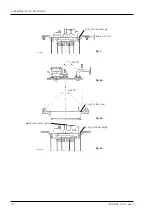

1. When drying with the vapour-phase process the bottom valve of the on-load tap-

changer shall be open and the cover of the on-load tap-changer, the O-ring and the

sealing of the suction pipe shall be removed. See section 3.2.2, point 1. To open the

bottom valve, proceed as follows:

2. Use the delivered bottom valve key to engage the internal hexagon hole of the bottom

valve. Open the valve by turning anticlockwise max. 4 turns.

3. When drying in a vacuum pan with the hot-air process, the top cover of the on-load

tap-changer, the O-ring and sealing of the suction pipe shall be removed. See section

3.2.2, point 1.

4.2 Observations after processing

CAUTION

To avoid seizing, do not operate the on-load tap-changer, neither during the drying process

nor afterwards, until it is filled with oil.

1. Make sure that all liquid has been drained from the selector switch housing. Close the

bottom valve. Tightening torque is approximately 15 Nm.

2. If a tie-in resistor from ABB is supplied, its screw joints are to be retightened (tightening

torque 15 Nm) and locked by the method specified by the transformer manufacturer.

4 Drying