Maintenance

130

10. Unplug the fiber optic cable from the module.

11. Unplug the terminal block from the module.

12. Remove the module mounting screws (four at top, two at bottom).

13. Disconnect the DC output busbars from the module. Beware not to drop the

screws inside the module!

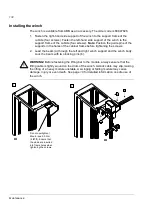

14. Assemble the module installation stand. See

Installing the installation stand

page

. Pay attention to the width: Select the right braces to match the width

of the stand to the width of the cubicle.

15. Fasten the module installation stand to the frame of the cubicle (2 × 5 screws).

Align the stand and the rails on which the module lies on in the cubicle. Adjust

the height of the feet.

Note:

Remove the cabinet hinge first if necessary.

WARNING!

The feet must lean on a solid floor. The cubicle may topple over when

the heavy module is pulled out if the stand is not supported properly.

16. Fasten the lifting bar of the winch to the two module lifting holes.

WARNING!

Before fastening the lifting bar, always ensure that the lifting cable is

tightly wound on the drum of the winch. A slack cable may slip, making the lifting of a

heavy module unstable. A swinging or falling module may cause damage, injury or

even death. See

Use of the hand-operated winch

(page

)

for more detailed

information on safe use of the winch.

17. Pull the module out of cubicle onto the installation stand. Keep the pipes and

wires away from the sharp edges.

18. Winch the module up.

19. Remove the module installation stand.

20. Winch the module down and lay it on a pallet.

WARNING!

The module is heavy and its centre of gravity is high. The module

topples over easily. Never manoeuvre it in upright position untied. It is highly

recommended to lay the module on its side before moving the pallet.

21. Move the pallet with the module aside.

22. Before installing a new module, check and service the quick connector through

which the AC output busbars or the cubicle connect to the module:

• Check the tightness of the motor cable connections at the quick connector:

70 N·m (52 lbf·ft).

• Clean all contact surfaces of the quick connector and apply a layer of suitable

joint compound eg, Isoflex® Topas NB 52 from Klüber Lubrication, onto them.

23. Install new module in reverse order.

Summary of Contents for ACS800-17LC

Page 1: ...ABB industrial drives Hardware manual ACS800 17LC Drives 55 to 5200 kW ...

Page 4: ......

Page 10: ...Update notice 6 ...

Page 18: ...Table of contents 12 ...

Page 26: ...Safety instructions 20 ...

Page 32: ...Introduction to the manual 26 ...

Page 60: ...Hardware description 54 ...

Page 74: ...Mechanical installation 68 ...

Page 114: ...Electrical installation 108 ...

Page 142: ...Maintenance 136 ...

Page 150: ...Internal cooling circuit 144 ...

Page 179: ...Dimensions 173 Frame sizes R7i R7i and R8i R8i bottom entry exit ...

Page 180: ...Dimensions 174 Frame sizes R7i R7i and R8i R8i marine units C121 ...

Page 182: ...www abb com drives www abb com drivespartners Contact us 3AUA0000065339 Rev B EN 2016 06 07 ...