To use the 3M Heat Trace Bill of Materials Tool, visit

3M.ca/HeatTrace

26

Table 2.1 Cable Selection

Start up temperature 20°F

-7°C

Start up temperature 0°F

-18°C

Voltage

Max Circuit Length

(feet)

Max Ckt Length (meters)

Voltage

Max Circuit Length

(feet)

Max Ckt Length

(meters)

15A Breaker

120 V

208 V

240 V

100

185

190

31

57

58

15A Breaker

120 V

208 V

240 V

80

145

150

25

45

46

20A Breaker

120 V

208 V

240 V

135

245

250

42

75

77

20A Breaker

120 V

208 V

240 V

105

190

200

33

58

61

30A Breaker

120 V

208 V

240 V

175

350

350

54

107

107

30A Breaker

120 V

208 V

240 V

155

290

295

48

89

90

40A Breaker

120 V

208 V

240 V

175

350

350

54

107

107

40A Breaker

120 V

208 V

240 V

175

350

350

54

107

107

Note: Due to TTS™ Self-Regulating Heating Cable self-regulating feature, TTS™ Self-Regulating Heating Cable will increase power when exposed to ice and snow.

When the cable has cleared the area, the power output will decrease, reducing energy consumption.

The following three considerations are used to help determine heating cables and lengths:

1. Operating voltage:

TTS™ Self-Regulating Heating Cable

s

are available in two voltage groups: 110-120 Vac and

208-240 Vac.

Determine what voltage is available for use with heat tracing.

2. Branch circuit breakers:

Use

Table

2.1

, Cable Selection, to match the TTS™ Self-Regulating Heating Cable

s

circuit

length with the available branch circuit breaker size. If a known branch circuit breaker size is being used, match this

value with the corresponding TTS™ Self-Regulating Heating Cable

s

circuit length. If breaker size will be dictated by

heating cable requirements, determine the optimal TTS™ Self-Regulating Heating Cable

s

circuit lengths based on the

project size and cable layout.

3. x:

The maximum circuit lengths shown in

Table

2.1

are based on TTS™ Self-Regulating Heating Cable

s

start-up at an

ambient temperature of

7° C (20° F)

. Because the power output of TTS™ Self-Regulating Heating Cables

will vary to

meet the needs of the surrounding environment, the operating load will vary.

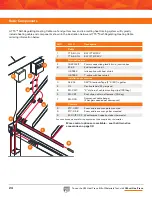

A TTS™ Self-Regulating Heating Cable Roof and Gutter Heat Tracing System will require the following components:

• 18-SXG kit

• ET-4S

Additional installation accessories are detailed on page 41-47.

1. The junction boxes used for connecting the heating cable to power should, whenever possible, be located under a

roof overhang or similar area to avoid direct exposure. Provide drip loops where the power feed and heating cable

enter the junction box.

2. On larger projects with multiple circuits or where the design layout permits, locate the power connection points for

two circuits in the same location to reduce power feed conduits.

Step 2: Select proper heating cables and lengths.

Step 4: choose TTS™ Self-Regulating Heating Cable installation accessories.

Step 3: Cable layout - specify power connection locations.

Don’t forget:

To aid in planning, TTS™ Self-Regulating Heating Cable multipliers are given for the most common

roofing material types. Use these multipliers, shown in

Tables 2.2.1

and

2.2.2

, to determine the footage of TTS™

Self-Regulating Heating Cable required based on the variables indicated. Be sure to add extra cable to get from the

heat-traced area back to the power connection point.

Summary of Contents for TTS-5-1-OJ

Page 7: ...To use the 3M Heat Trace Bill of Materials Tool visit 3M ca HeatTrace 7 2 2 2 2 2 3 3 3 3...

Page 8: ...To use the 3M Heat Trace Bill of Materials Tool visit 3M ca HeatTrace 8 Pipe Freeze Protection...

Page 11: ...To use the 3M Heat Trace Bill of Materials Tool visit 3M ca HeatTrace 11 4 5 6 7 9 1 8 3 2...