To use the 3M Heat Trace Bill of Materials Tool, visit

3M.ca/HeatTrace

To use the 3M Heat Trace Bill of Materials Tool, visit

3M.ca/HeatTrace

13

Expected Minimum Ambient Temperature

Minimum Start-Up Temperature

Insulation Material and Thickness

Supply Voltage

Generally, this number is obtained from weather data compiled for an area and is based on recorded historical data.

There are times, however, when the minimum ambient will be a number other than the minimum outside air temperature.

Piping located inside of unheated buildings or in unconditioned attics may be subject to freezing, but may have different

minimum ambient.

This temperature differs from the minimum expected ambient in that the heating cable will typically be energized at a

higher ambient temperature. This temperature will have an effect on the maximum circuit length and circuit breaker

sizing for a given application.

The selection charts in this guide (see pages 14-15) are based on fibreglass insulation. These charts may also be used

with polyisocyanurate or mineral wool insulations of the same thickness. If insulation materials other than these are

used, contact 3M (

for a selection chart supplement that corresponds with the

insulation material.

TTS™ Self-Regulating Heating Cables are designed in two voltage groups:

1. 110-120 Vac

2. 208-240 Vac

Determine what voltage(s) are available at a facility for use with heat tracing.

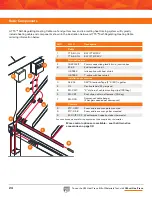

Step 2: Select the proper TTS™ Self-Regulating Heating Cable.

Using the pipe diameter, insulation thickness and minimum expected ambient, find the recommended heating cable

using

Selection Chart 1.2.1 Metallic Piping

on page 14, or

Selection Chart 1.2.2 Non-metallic Piping

on page 15. If the

pipe size or insulation information does not appear, contact 3M at

1. Select the vertical column headed by a low ambient temperature that is equal to or lower than that expected in

your area.

2. Use the table section which corresponds to the insulation thickness shown in the left-hand column.

3.

Based on the pipe diameter(s) of the application, read across the table to the low ambient temperature and note the

TTS™ Self-Regulating Heating Cable recommended for that set of conditions.

4. Note that larger pipe sizes and lower ambient temperatures may require multiple passes of heating cable.

5.

On piping 1-1/4" (25.4 mm - 6.4 mm) in diameter and smaller, the insulation must be one pipe size larger to

accommodate the heating cable [i.e., use insulation sized for a 1" (25.4 mm) diameter pipe if the pipe to be insulated

is 3/4" (19.1 mm) diameter].

6.

For pipe sizes larger than listed or for maintain temperatures other than 5°C (40°F), contact 3M at

Note: Heat loss calculations are based on IEEE Std 515-1997, Equation A.1, with the following provisions:

• Piping insulated with glass fibre in accordance with ASTM Std C547

• Pipes located outdoors in the noted ambient with a 40 km/h (25 mph) wind

• A 10% safety factor has been included

Note: Chart may also be used with polyisocyanurates or mineral wool of the same thickness.

Summary of Contents for TTS-5-1-OJ

Page 7: ...To use the 3M Heat Trace Bill of Materials Tool visit 3M ca HeatTrace 7 2 2 2 2 2 3 3 3 3...

Page 8: ...To use the 3M Heat Trace Bill of Materials Tool visit 3M ca HeatTrace 8 Pipe Freeze Protection...

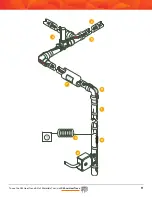

Page 11: ...To use the 3M Heat Trace Bill of Materials Tool visit 3M ca HeatTrace 11 4 5 6 7 9 1 8 3 2...