To use the 3M Heat Trace Bill of Materials Tool, visit

3M.ca/HeatTrace

20

Product Specifications

Ratings

Data Sheet — TTS™ Self-Regulating Heating Cable for Pipe Freeze Protection

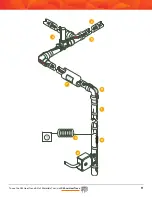

1

2

3

4

5

Construction

1 Nickel-Plated Copper Bus Wires (16 AWG)

2 Radiation Cross-Linked Semiconductive Heating Matrix

3 Radiation Cross Linked Dielectric Insulation

4 Tinned Copper Braid (BC)

5 Polyolefin Overjacket

Available watt densities

16, 26, 33 w/m @10° C (5,8,10 w/ft @50° F)

Supply voltages

110-120 or 208-240 vac

Max. Maintenance temperature

65°C (150°F)

Max. Continuous exposure temperature power off

85°C (185°F)

Minimum installation temperature

-51°C (-60°F)

Minimum bend radius

32 mm (1.25")

T-rating

T6 85°C (185°F)

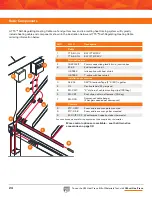

Basic Accessories

Power Connection:

All TTS™ Self-Regulating Heating Cables require an ECA, PCA or 18-SXG-KIT power connection kit

for terminating the circuit before connecting to power.

End-of-Circuit Termination:

TTS™ Self-Regulating Heating Cables require the ET-6C end cap for terminating the end

of the circuit.

Note: T-rating per the 1996 NEC, Tables 500-3(d), 505-10(b) and as verified by Factory Mutual Research and the Canadian Standards Association.

Summary of Contents for TTS-5-1-OJ

Page 7: ...To use the 3M Heat Trace Bill of Materials Tool visit 3M ca HeatTrace 7 2 2 2 2 2 3 3 3 3...

Page 8: ...To use the 3M Heat Trace Bill of Materials Tool visit 3M ca HeatTrace 8 Pipe Freeze Protection...

Page 11: ...To use the 3M Heat Trace Bill of Materials Tool visit 3M ca HeatTrace 11 4 5 6 7 9 1 8 3 2...