4.6.2

Connection in NFPA 79 Applications

In applications where the NFPA 79 (Electrical Standard for industrial machinery) applies the

enclosed

cable glands can be used.

Attention!

•

Independent of the type and manner of the conduit / tube connection, correct connection of the

supply line(s), the safety of people and objects must be provided at all times.

•

The locking screws used within the MK116 and MK152 series are only for shipment. For installation

the locking screws must be removed.

•

It must be used a connection technology suitable for the environmental type rating of the drive!

4.7

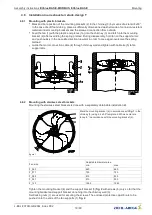

Fan designs A and D (without nozzles)

For attachment to

fi

xed motor

fl

ange use screws with property class A2-70 (stainless steel) to EN ISO

4014 and provide with suitable screw locking.

Permissible tightening torques M

A

Motor size

D

D

G

Thread size

M6

(Special application with 5-

pitch)

M8

M10

Stainless steel A2-70, friction coefcient

µ

ges = 0.12

7 Nm

17 Nm

33 Nm

Screw penetration

≥

1.5 x d

≥

1.5 x d

≥

1.5 x d

When using screws with different friction values or strength classes, different tightening torques may

be necessary.

Information

•

Pay attention to a suf

fi

cient screw-in length in the motor

fl

ange.

•

Excess screw length not permissible and it may result in the rotor being brushed against or blocked.

•

Every screwing case is different. The tightening torque adapted to it must be determined by the

appropriate screw tests.

•

Avoid structural damage or stress with installation. Make sure the surface is

fl

at and even.

•

In the case of a vertical motor axis, the respective lower drain hole must be open.

•

Secure fan connection cable with cable fasteners or cable clips.

A minimum head gap

“

A

”

of 2.5 mm in all installation

positions but especially in installation position H (horizon-

tal motor shaft) is necessary. Distortion due to uneven

surface may lead to fan failure due to brushing against the

fan wheel.

Assembly instructions

ECblue BASIC-MODBUS, ECblue BASIC

Mounting

L-BAL-F079D-GB 2044 Index 002

Part.-No.

18/80