DECK MECHANISM ADJUSTMENT

4-15

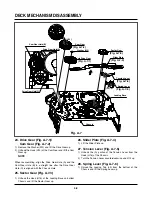

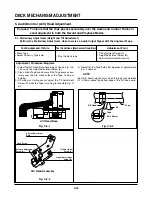

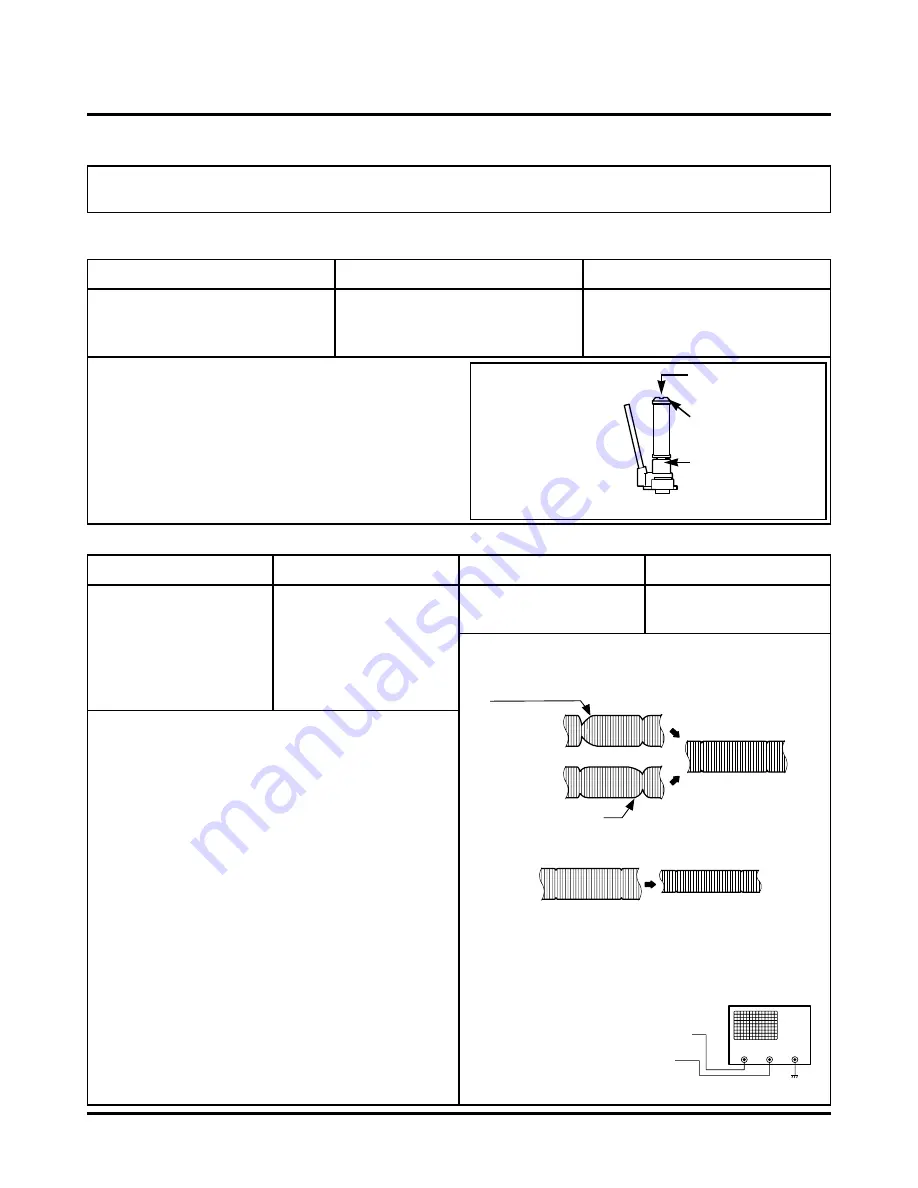

4.Guide Roller Height Adjustment

Adjustment Procedure

1) Confirm that the Tape runs along the Tape Guide Line of the

Lower Drum.

2) If the Tape runs at the Bottom of the Guide Line, turn the

Guide Roller Height Adjustment Screw Clockwise.

3) If it runs at the Top, turn Counterclockwise.

4) Adjust the Height of the Guide Roller to be guided to the

Guide Line of the Lower Drum from the Starting and Ending

Point of the Drum.

Purpose: To regulate the Height of the Tape so that the Bottom of the Tape runs along the

Tape Guide Line on the Lower Drum.

Test Equipment/ Fixture

• Post Height Adjusting Driver

Test Conditions (Mechanism Condition)

• Play or Review Mode

Adjustment Point

• Guide Roller Height Adjustment

screws on the Supply and Take-Up

Guide Rollers.

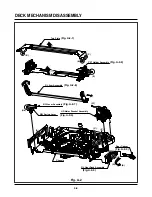

Fig. C-4-1

Upper Flange

Guide Roller

Retaining Screw

Guide Roller Height

Adjustment screw

ADJUSTMENT DIAGRAM

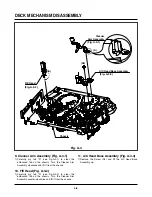

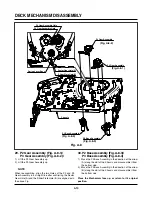

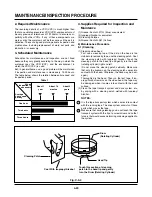

Test Equipment/Fixture

• Oscilloscope

• Alignment Tape

• Post Height Adjusting

Driver

Test Equipment Connection Points

• CH-1:PB RF Envelope

• CH-2:NTSC: SW 30Hz

PAL: SW 25Hz

• Head Switching Output

Point

• RF Envelope Output

Point

Test Conditions VCR (VCP) State

• Play an Alignment Tape

Adjustment Point

• Guide Roller Height

Adjustment Screws

Fig. C-4-2

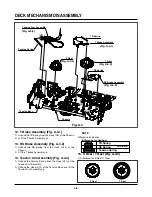

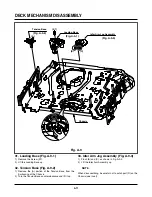

Fig. C-4-3

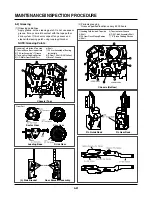

P3 POST

ADJUSTMENT

P2 POST

ADJUSTMENT

Turn the Roller Guide Height

Adjustment Screw slightly

to flatten the waveform.

Tracking control at center

RF ENVELOPE OUTPUT TEST POINT

OSCILLOSCOPE

HEAD SWITCHING OUTPUT TEST

POINT

Turn (Move) the tracking

control to both directions

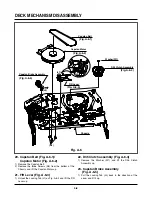

4-1. Preliminary Adjustment

4-2. Precise Adjustment

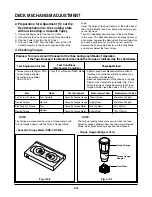

Adjustment Procedure

1) Play an Alignment Tape after connecting the Probe of the

Oscilloscope to the RF Envelope Output Test Point and

Head Switching Output Test Point.

2) Tracking Control (in PB Mode): Center Position (When

this Adjustment is performed after the Drum Assembly

has been replaced, set the Tracking Control so that the

RF Output is Maximum).

3) Height Adjustment Screw: Flatten the RF Waveform.

(Fig. C-4-2)

4) Turn (Move) the Tracking Control (in PB Mode)

Clockwise and Counterclockwise. (Fig. C-4-3)

5) Check that any Drop of RF Output is uniform at the

Start and End of the Waveform.

If the adjustment is excessive or insufficient the tape

will jam or fold.

NOTE

Waveform Diagrams

Connection Diagram

Содержание ABV341 Series

Страница 2: ......

Страница 36: ...3 34 3 35 2 TU IF CIRCUIT DIAGRAM PB REC...

Страница 39: ...3 40 3 41 5 JACK CIRCUIT DIAGRAM...

Страница 41: ...3 44 3 45 7 TIMER CIRCUIT DIAGRAM XBV343...

Страница 42: ...3 46 3 47 8 TIMER CIRCUIT DIAGRAM XBV342...

Страница 45: ...3 52 3 53 PRINTED CIRCUIT DIAGRAMS 1 MAIN P C BOARD LOCATION GUIDE...

Страница 65: ...02 12 04 R17149A ZENITH DAP202K 3 80 3 81 6 JACK CIRCUIT DIAGRAM...

Страница 70: ...LOCATION GUIDE 3 90 3 91 PRINTED CIRCUIT DIAGRAMS 1 MAIN P C BOARD TOP VIEW...

Страница 71: ...LOCATION GUIDE 3 92 3 93 2 MAIN P C BOARD BOTTOM VIEW...

Страница 92: ...3 114 2 Audio related Signal ASDAT3 IC501 PIN 157 ABCK IC501 PIN 148 ALRCK IC501 PIN 149 ASDATA3 FIG 14 2...

Страница 98: ...3 121 3 122 2 RF DSP SERVO CIRCUIT DIAGRAM CD DVD LD will not on COMBI SCART MTK 03 3 25 SR17445A...

Страница 99: ...3 123 3 124 3 AUDIO CIRCUIT DIAGRAM COMBI SCART MTK 03 3 25 SR17447A...

Страница 100: ...3 125 3 126 4 AV JACK CIRCUIT DIAGRAM COMBI SCART MTK 03 3 25 SR17446A...

Страница 103: ...3 131 3 132 PRINTED CIRCUIT DIAGRAMS 1 MAIN P C BOARD LOCATION GUIDE...

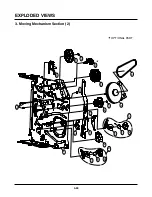

Страница 110: ...EXPLODED VIEW 1 Deck Mechanism Exploded View 5 1 CONTENTS SECTION 5 MECHANISM OF DVD PART MTK MODEL...

Страница 134: ...4 22 GEAR F R GEAR AY P2 P3 F R Lever Tension Base Boss CAM...