Page 29

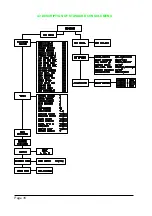

6.1 ANALYSIS OF ALARMS DISPLAYED ON THE CONSOLE

1 WATCH DOG

AL 8 MDI

The test is executed at the key turn-on, at the stand-by and on running. Possible

causes:

a) Watch-dog hardware circuit not OK;

b) Software not OK.

2 EEPROM KO

AL 13 MDI

Fault in the area of memory where the adjustment parameters are stored. This

Alarm inhibits machine operation. If the fault continues when the Key Switch is re-

cycled, replace the logic. If the fault disappears, the previously stored Parameters

will have been replaced by the default parameters.

3 CHECK UP NEEDED

AL 99 MDI

The "check up type" parameter is active and the time from last check up is > 300

hours.

4 INCORRECT START

AL 79 MDI

Alarm generated by an incorrect Starting Sequence. Possible causes:

a) The TILLER microswitch is stuck or failed.

b) Error in the starting sequence from the operator.

c) Error in the wiring.

5 FORW + BACK

AL 80 MDI

This check is made continually. The alarm is generated when forward and reverse

direction are requested simultaneously. Possible causes:

a) Error in Wiring.

b) Welding or Failure of a direction switch.

c) Error in the starting sequence from the operator.

6 CAPACITOR CHARGE

AL 60 MDI

This check is made during the initial diagnosis. This Alarm is generated if the

Capacitors are not charged within 500ms after the Key Switch is closed. Probable

cause is failure inside the power block.

7 VMN NOT OK

AL 32 MDI

This test is performed at rest, with the general Contactor Closed, and also during

operation. At rest if VMN is lower than battery voltage this Alarm is generated.

During operation this Alarm is generated if VMN doesn’t follow the duty-cycle of the

chopper. Possible causes:

a) Incorrect Motor connection.

b) Short circuit motor windings to chassis.

c) Defect in the power unit.