Page 9

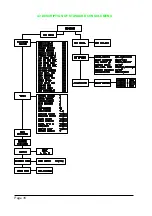

2.6 SEM-X CHOPPER DIAGNOSIS

The microprocessor continually monitors the chopper and carries out diagnostic

procedures on the main functions.

The diagnosis is made in 4 points:

1)

Diagnosis on key Switch closing that checks: the Watch Dog Circuits, the current

sensors, VMN point, Main Contactor Driver, if the switch sequence for operation is

correct, and if the output of the accelerator or tiller is correct.

2)

Standby Diagnosis at rest that checks: VMN Point, Main Contactor Driver, Current

Sensor, Watchdog, Brake, Vfield, NPOT.

3)

Diagnosis during operation that checks: Watchdog, VMN Point, Current (field and

armature), Main Contactor, Brake, NPOT.

4)

Continuos Diagnosis that checks: Chopper temperature, Battery Voltage.

Diagnosis is provided in 3 ways. The Red Led connected to Connector B will flash a

certain number of times for a given Alarm (See Listings), or the Digital Console may be

used or MDI. A permanent Alarm will be displayed on the Console immediately. An

intermittent Alarm will be recorded in the Alarm library.

2.7 THERMAL CONSIDERATIONS

- The heat generated by the power block must be dissipated. For this to be possible,

the compartment must be ventilated and the heat sink materials ample.

- The heat sink material and system should be sized on the performance requirement

of the machine. Abnormal ambient air temperatures should be considered. In

situations where either ventilation is poor, or heat exchange is difficult, forced air

ventilation should be used.

- The thermal energy dissipated by the power block module varies and is dependent

on the current drawn and the duty cycle.