Page 11

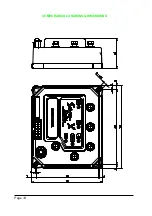

3 INSTALLATION

Install the chopper baseplate onto a flat metallic surface that is clean and unpainted.

Apply a thin layer of thermo-conductive grease between the two surfaces to permit

better heat dissipation.

Despite the protection provided against external agents, the continuous attack of

corrosive elements and substances may cause oxidization of connector contacts,

resulting in bad operation. Remember this point when deciding the installation position

on the vehicle.

Fix the chopper using the special holes located on the baseplate.

Verify that the wiring of the cable terminals and connectors has been carried out

correctly. Ensure that suppression devices are fitted to the coils not protected by the

SEM-X itself.

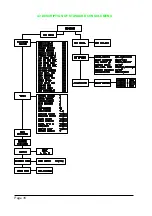

3.1 CONNECTION CABLES

For the auxiliary circuits use cables better or equal to 0.5mm² section.

For power connections to the motor armature and battery use cable of 10mm² section.

For the Field connections use cable of 4mm² section.

For the optimum chopper performance, the cables to the battery should be run side by

side and be as short as possible.

3.2 CONTACTORS

A Line Contactor, designed for Continuous Operation should be installed. This

contactor should be fitted with a coil corresponding to the battery voltage. The current

absorbed by the coil must not be greater than 3A.

Suppression for this contactor coil is within the chopper. Do not use external

suppression. For any Contactor using external suppression, ensure that connections

are made respecting correct polarity.

3.3 FUSES

- Use a 6.3A Fuse for protection of the auxiliary circuits.

- For protection of the power unit, refer to diagrams.. The Fuse value shown is the

maximum allowable. For special applications or requirements these values can be

reduced.

- For Safety reasons, we recommend the use of protected fuses in order to prevent the

spread of fused particles should the fuse blow.