4-14

<Toc> <Ind>

TI 05C01E02-01E

1st Edition : Oct. 31, 2001-00

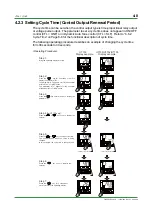

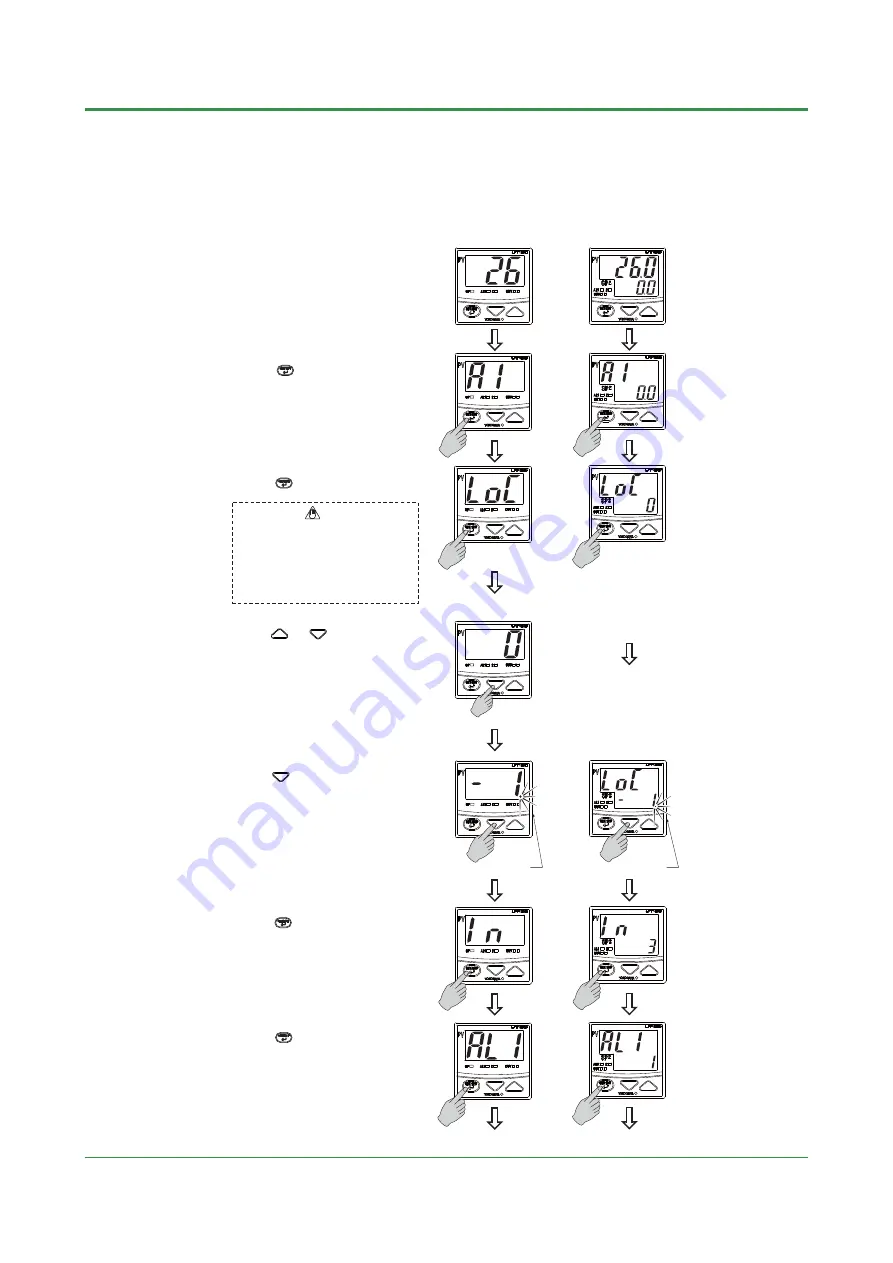

The following operating procedure describes an example of setting the “deviation high

and low limit” (setpoint: 7) for the alarm-1 type, and “5

°

C“ for the alarm 1 hysteresis.

Step 1:

Bring the operating display into view.

UT130

Display example

UT150/UT152/UT155

Display example

Step 3:

Press the key several times to display

the parameter "CTL"(control mode).

Set "-1" to enter the setup parameter

setting display. But if "LOC" = 1 or 2 is

already set, the parameter value can not

be changed by setting "LOC" = -1 only. To

change the parameter value, set "LOC" = 0

at first (for disabling key lock), then set

"LOC" = -1 once again

NOTE

Step 5:

Press the key to display "-1".

Step 6:

Press the key once.

Flashes during change.

Flashes during change.

Step 2:

Press the key for 3 seconds or more

to display the parameter "A1".

The parameter "A1" appears only for the

controller with the "/AL" or" /HBA" option.

The parameter "CTL" appears for the

controller without the "/AL" or" /HBA" option,

and in this case, the alarm function is not

available.

Step 7:

Press the key several times to display

the parameter "AL1" (alarm 1 type).

The parameter "AL1" appears only for the

controller with the "/AL" or" /HBA" option.

To the next page

To the next page

Step 4

(for UT130 only)

:

Press the or key once to display

the setpoint.

<Operating Procedure>

Содержание UT130

Страница 2: ...Blank Page ...

Страница 4: ...Blank Page ...

Страница 8: ...Blank Page ...

Страница 30: ...Blank Page ...

Страница 48: ...Blank Page ...

Страница 60: ...Blank Page ...

Страница 72: ...Blank Page ...