TRANSMISSION-KBW SERIES

217

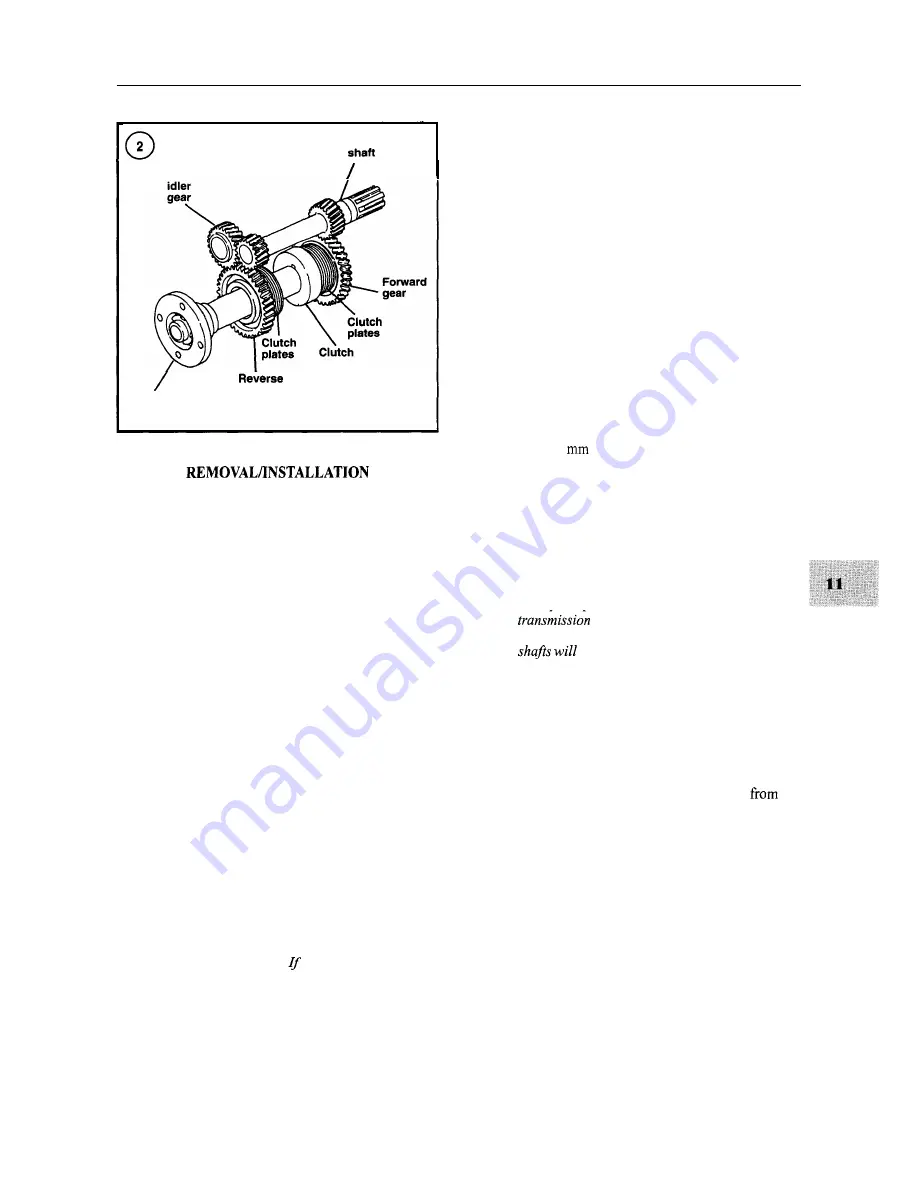

Input

Reverse

gear

Coupling flange

The following procedure addresses units that are acces-

sible. In some cases, it may be necessary to remove the en-

gine and transmission as a unit before removing the

transmission from the engine. Refer to Chapter Six if en-

gine removal is necessary.

1. If not previously disconnected, disconnect the remote

control cable from the transmission shift lever.

2. If not previously disconnected, disconnect the drive

coupling from the transmission drive flange.

3. Remove the bolts that secure the transmission to the

engine bellhousing.

4. Remove the transmission from the engine.

5. Reinstall the transmission by reversing the removal

procedure. Make sure

to align the splines on the transmis-

sion input shaft and the drive disc during installation.

Tighten the transmission retaining bolts to the torque

specified in Table 2.

OVERHAUL

Refer to Figure 3.

NOTE

Overhaul of the

KB

W transmission requires

special tools, which can be obtained from

Yanmar or fabricated.

the special tools

are not available, have a Yanmar dealership

overhaul the transmission.

Disassembly

1.

Remove the drain plug and drain the transmission oil.

2. Position the transmission in a vise with soft jaws so the

input shaft is held by the vise jaws.

3. The output flange retaining nut is staked. Use a chisel

to cut away the staked portion so the nut will rotate.

4. Install a tool that will prevent rotation of the output

flange.

5. Unscrew the output flange retaining nut.

6. Remove the oil dipstick.

7. Make match marks on the shifter cover and the trans-

mission case so the shifter can be installed in its original

position.

8. Remove the shifter retaining bolts and remove the

shifter assembly.

9. Remove the transmission from the vise.

10. Using an 8

Allen wrench, remove the shift bar re-

taining plug (68, Figure 3) in the rear of the case.

11. Install a 10 mm bolt into the end of the shift bar, then

pull the shift bar (58, Figure 3) out of the case while also

removing the shift fork (57).

12. Remove the transmission mounting flange retaining

bolts.

NOTE

In Step 13, position the transmission so the

input shaft is up when remov-

ing the mountingflange so the transmission

not fall out.

13. Tap on the mounting flange using a soft-faced ham-

mer to dislodge the flange. Position the transmission with

the input shaft up, then remove the flange from the trans-

mission case.

14. Remove the output shaft assembly from the transmis-

sion case and set aside for disassembly.

15. Remove the intermediate shaft assembly

the

transmission case and set aside for disassembly.

16. Remove the input shaft assembly from the transmis-

sion case and set aside for disassembly.

17. Using a large screwdriver, pry out the oil seal in the

transmission case. Be careful not to damage the case or

the adjacent bearing race.

18. Using a large screwdriver, pry out the oil seal in the

transmission mounting flange. Be careful not to damage

the case or the adjacent bearing race.

19. If inspection indicates additional disassembly is nec-

essary, refer to the following sections.

Содержание 1GM10

Страница 1: ...YANMAR DIESEL INBOARD SHOP MANUAL ONE TWO 8 THREE CYLINDER ENGINES...

Страница 6: ......

Страница 7: ......

Страница 9: ......

Страница 10: ......

Страница 11: ......

Страница 12: ......

Страница 13: ......

Страница 16: ......

Страница 17: ......

Страница 18: ......

Страница 19: ......

Страница 20: ......

Страница 21: ......

Страница 22: ......

Страница 23: ......

Страница 24: ......

Страница 25: ......

Страница 26: ......

Страница 27: ......

Страница 28: ...GENERAL INFORMATION 21 Bearing Blocks Press Shaft arm Bearing Spacer Press k 4 bed...

Страница 36: ...30 CHAPTER TWO CHARGING SYSTEM TYPICAL Battery switch...

Страница 39: ......

Страница 44: ...38 CHAPTER TWO LUBRICATION SYSTEM 2GM AND 2GM20 MODELS...

Страница 45: ...TROUBLESHOOTING 39 LUBRICATION SYSTEM 3GM 3GM30 3HM AND 3HM35 MODELS 3HM AND 3HM35 MODELS Filter...

Страница 46: ......

Страница 50: ......

Страница 52: ......

Страница 54: ......

Страница 55: ......

Страница 57: ......

Страница 58: ......

Страница 64: ......

Страница 66: ......

Страница 70: ......

Страница 71: ......

Страница 77: ......

Страница 78: ......

Страница 79: ......

Страница 80: ......

Страница 81: ......

Страница 82: ......

Страница 89: ......

Страница 90: ......

Страница 91: ......

Страница 92: ......

Страница 93: ......

Страница 94: ......

Страница 95: ......

Страница 96: ......

Страница 97: ......

Страница 98: ......

Страница 99: ......

Страница 100: ......

Страница 101: ......

Страница 102: ......

Страница 112: ...106 CHAPTER SIX...

Страница 114: ......

Страница 123: ......

Страница 124: ......

Страница 125: ......

Страница 126: ......

Страница 129: ......

Страница 130: ......

Страница 131: ......

Страница 133: ......

Страница 134: ......

Страница 135: ......

Страница 136: ......

Страница 145: ...FUEL INJECTION AND GOVERNOR SYSTEMS 139 FUEL INJECTION SYSTEM Fuel tank hose fuel pipe...

Страница 148: ......

Страница 149: ......

Страница 150: ......

Страница 151: ......

Страница 152: ......

Страница 153: ......

Страница 154: ......

Страница 155: ......

Страница 156: ......

Страница 157: ......

Страница 158: ......

Страница 165: ......

Страница 166: ...160 CHAPTER EIGHT SEAWATER COOLING SYSTEM 1GM AND 1GMlO Mixing elbow Rubber hose I Drain Seacock except 1GM1OC...

Страница 167: ...COOLING SYSTEM 161 SEAWATER COOLING SYSTEM 2GM AND 2GM20 U type mixing elbow Rubber hose Seacock except 2GM20C...

Страница 170: ...164 CHAPTER EIGHT CLOSED COOLING SYSTEM TYPICAL rnlxlng elbow Joint...

Страница 172: ......

Страница 174: ......

Страница 175: ......

Страница 176: ......

Страница 177: ......

Страница 184: ......

Страница 190: ......

Страница 196: ......

Страница 197: ......

Страница 201: ......

Страница 202: ......

Страница 204: ......

Страница 205: ......

Страница 208: ......

Страница 209: ......

Страница 219: ......

Страница 224: ...218 CHAPTER ELEVEN...

Страница 231: ......

Страница 235: ......