OPERATION. LUBRICATION. MAINTENANCE AND TUNE-UP

47

bleed plug

Filter element

I

t

Canister

fuel and maintain the fuel filter and fuel system compo-

nents to prevent a fuel system malfunction.

WARNING

Serious fire hazards always exist around

diesel fuel. Do not allow any smoking in ar-

eas where fuel is present. Always have afire

rated for fuel and electrical

fires, on hand when refueling or servicing

any part of the fuel system.

Fuel lines

Periodically inspect all fuel lines for leakage and dam-

age. Replace or tighten them as required. Do not

overtighten a fitting to try to stop a leak; overtightening

may damage the fitting threads or the fuel line sealing sur-

faces.

Air that enters the fuel system due to a damaged fuel

line or loose connection may cause the engine to missfire.

Bleed the fuel system as described in this chapter.

Using clean fuel and maintaining the fuel system are

extremely important when operating a diesel engine. Die-

sel fuel, in addition to its obvious

as fuel, pro-

vides lubrication for various components of the injection

system. Due to close operating tolerances, dirty fuel can

cause major damage to the fuel injection pump and injec-

tors. The engine is equipped with a fuel filter

(Figure 6,

typical) to remove dirt from the fuel before it enters the

fuel injection pump.

After every

50 hours of operation, or more frequently if

necessary, remove and disassemble the fuel filter and

clean the inside of the fuel bowl and filter element. The

filter body contains a replaceable element. Replace the el-

ement after every

250 hours of operation or more fre-

quently if dirt clogs the element after fewer hours of

operation. It is a good practice to replace the fuel filter ev-

ery season or if the engine has not been operated for an ex-

tended period.

NOTE

The boat may be equipped with additional

fuel filters. Be sure to clean and maintain

thosefilters according to the manufacturer

instructions.

NOTE

If

the fuel filtering system is inadequate to

properly protect the engine, consult with a

marine dealership that has experience with

diesel engines for fuel filter recommenda-

tions.

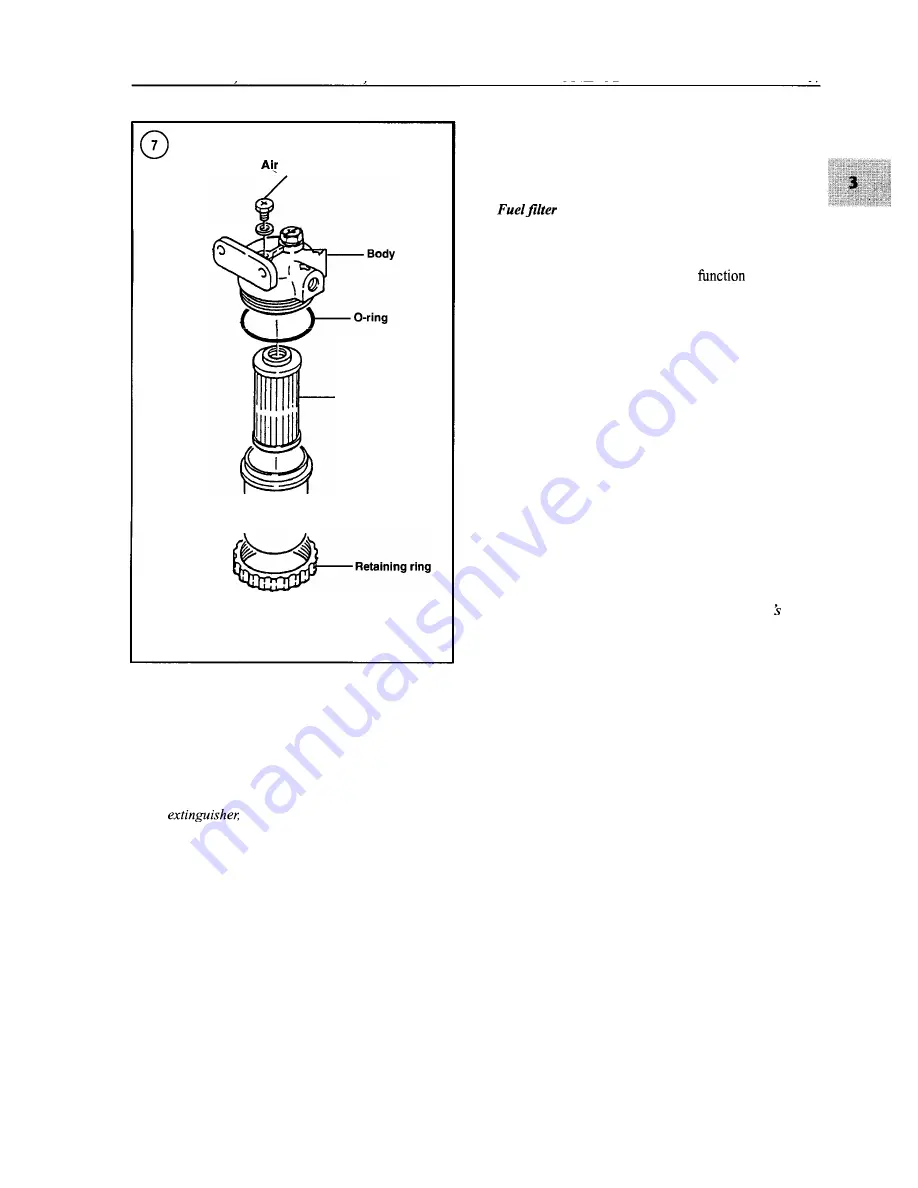

Refer to

Figure 7 when using the following procedure

to clean the filter or replace the filter element:

1. Position a receptacle under the filter to catch spilled

fuel.

2. Unscrew the retaining ring and remove the canister

and filter element. Note that the O-ring may remain on the

filter body or on the canister.

3. Remove the element from the canister. If dirty or dam-

aged, discard the element.

4.

Clean the canister in clean diesel fuel.

5. Install the filter element in the canister.

6. Install a new O-ring on the canister.

7.

Install the canister on the filter body, then install the re-

tainer ring and tighten it hand-tight.

Содержание 1GM10

Страница 1: ...YANMAR DIESEL INBOARD SHOP MANUAL ONE TWO 8 THREE CYLINDER ENGINES...

Страница 6: ......

Страница 7: ......

Страница 9: ......

Страница 10: ......

Страница 11: ......

Страница 12: ......

Страница 13: ......

Страница 16: ......

Страница 17: ......

Страница 18: ......

Страница 19: ......

Страница 20: ......

Страница 21: ......

Страница 22: ......

Страница 23: ......

Страница 24: ......

Страница 25: ......

Страница 26: ......

Страница 27: ......

Страница 28: ...GENERAL INFORMATION 21 Bearing Blocks Press Shaft arm Bearing Spacer Press k 4 bed...

Страница 36: ...30 CHAPTER TWO CHARGING SYSTEM TYPICAL Battery switch...

Страница 39: ......

Страница 44: ...38 CHAPTER TWO LUBRICATION SYSTEM 2GM AND 2GM20 MODELS...

Страница 45: ...TROUBLESHOOTING 39 LUBRICATION SYSTEM 3GM 3GM30 3HM AND 3HM35 MODELS 3HM AND 3HM35 MODELS Filter...

Страница 46: ......

Страница 50: ......

Страница 52: ......

Страница 54: ......

Страница 55: ......

Страница 57: ......

Страница 58: ......

Страница 64: ......

Страница 66: ......

Страница 70: ......

Страница 71: ......

Страница 77: ......

Страница 78: ......

Страница 79: ......

Страница 80: ......

Страница 81: ......

Страница 82: ......

Страница 89: ......

Страница 90: ......

Страница 91: ......

Страница 92: ......

Страница 93: ......

Страница 94: ......

Страница 95: ......

Страница 96: ......

Страница 97: ......

Страница 98: ......

Страница 99: ......

Страница 100: ......

Страница 101: ......

Страница 102: ......

Страница 112: ...106 CHAPTER SIX...

Страница 114: ......

Страница 123: ......

Страница 124: ......

Страница 125: ......

Страница 126: ......

Страница 129: ......

Страница 130: ......

Страница 131: ......

Страница 133: ......

Страница 134: ......

Страница 135: ......

Страница 136: ......

Страница 145: ...FUEL INJECTION AND GOVERNOR SYSTEMS 139 FUEL INJECTION SYSTEM Fuel tank hose fuel pipe...

Страница 148: ......

Страница 149: ......

Страница 150: ......

Страница 151: ......

Страница 152: ......

Страница 153: ......

Страница 154: ......

Страница 155: ......

Страница 156: ......

Страница 157: ......

Страница 158: ......

Страница 165: ......

Страница 166: ...160 CHAPTER EIGHT SEAWATER COOLING SYSTEM 1GM AND 1GMlO Mixing elbow Rubber hose I Drain Seacock except 1GM1OC...

Страница 167: ...COOLING SYSTEM 161 SEAWATER COOLING SYSTEM 2GM AND 2GM20 U type mixing elbow Rubber hose Seacock except 2GM20C...

Страница 170: ...164 CHAPTER EIGHT CLOSED COOLING SYSTEM TYPICAL rnlxlng elbow Joint...

Страница 172: ......

Страница 174: ......

Страница 175: ......

Страница 176: ......

Страница 177: ......

Страница 184: ......

Страница 190: ......

Страница 196: ......

Страница 197: ......

Страница 201: ......

Страница 202: ......

Страница 204: ......

Страница 205: ......

Страница 208: ......

Страница 209: ......

Страница 219: ......

Страница 224: ...218 CHAPTER ELEVEN...

Страница 231: ......

Страница 235: ......