1 - 17

GEN

INFO

FEATURES

FUEL INJECTION SYSTEM

Operation and control

The fuel injection timing, injection duration, ignition timing, and the coil energizing duration are con-

trolled by the ECU. To determine the basic injection timing, the ECU calculates the intake air volume

through the signals from the intake air pressure sensor, throttle position sensor, cylinder identifica-

tion sensor, and crankshaft position sensor.

Furthermore, the ECU calculates the final injection timing by adding the following compensations to

the aforementioned basic injection duration: those obtained from the state of acceleration, as well

as those based on the signals from various sensors such as the coolant temperature, intake tem-

perature, atmospheric, and exhaust pipe oxygen concentration level. At the same time, the ECU

assesses the crankshaft position through the signals from the cylinder identification sensor and the

crankshaft position sensor. Then, when the ECU determines that it is time to inject fuel, it sends an

injection command to the injectors. Furthermore, the ECU also controls the length of time the coil is

energized by calculating the ignition timing and the coil energizing duration based on the signals

from these sensors.

Determining the basic injection duration

The intake air volume determines the basic injection duration. In order to operate the engine in an

optimal condition, it is necessary to supply fuel at an air-fuel ratio that corresponds appropriately to

the volume of intake air that is constantly changing, and to ignite it an appropriate timing. The ECU

controls the basic injection duration based on the intake air volume and engine speed data.

Detection of intake air volume

The intake air volume is detected primarily through the signals from the throttle position sensor and

the intake air pressure sensor. The intake air volume is determined in accordance with the signals

from the atmospheric pressure sensor, intake temperature sensor, and the engine speed data.

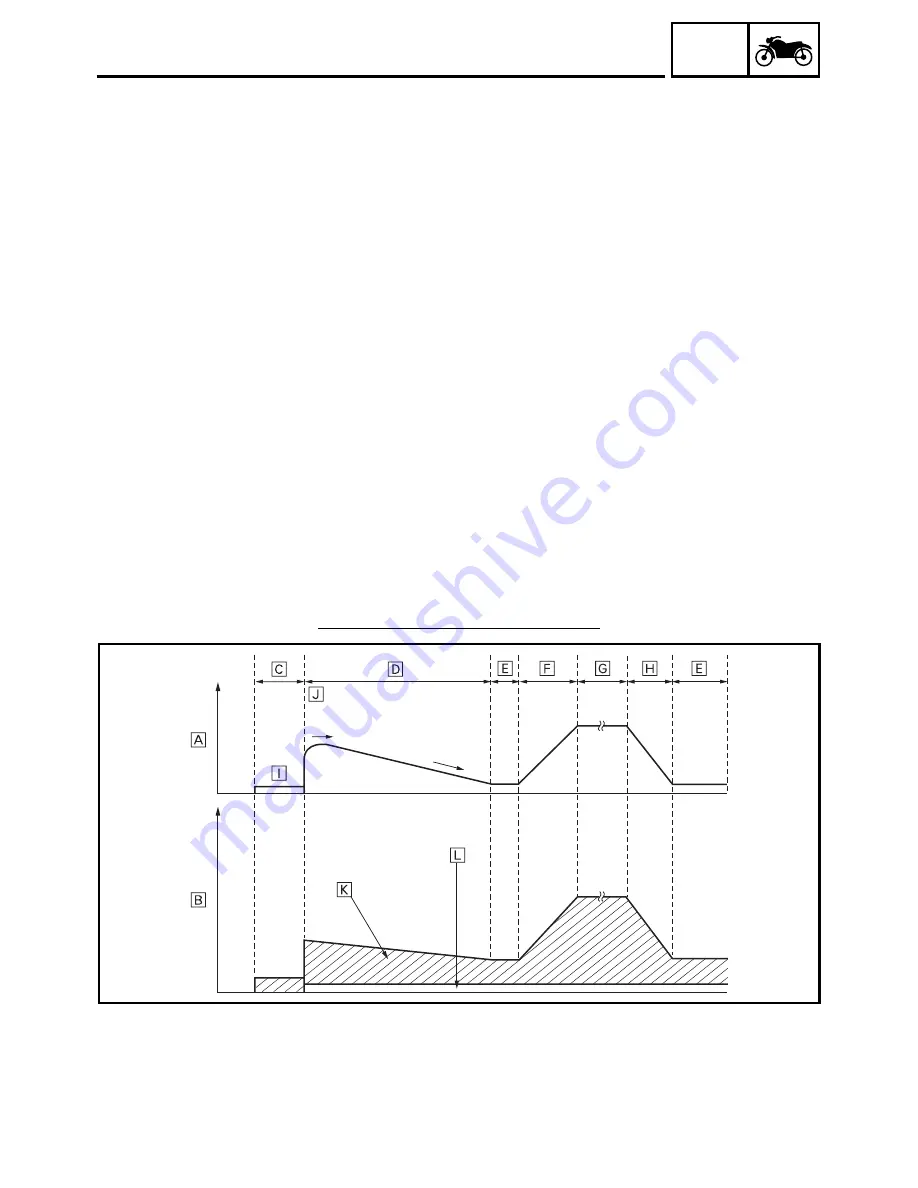

Composition of basic injection duration

È

RPM

É

Injection duration

Ê

Cranking

Ë

Warm-up

Ì

Idle

Í

Acceleration

Î

Constant

Ï

Deceleration

Ð

Start

Ñ

After start

Ò

Basic injection dura-

tion

Ó

Voltage compensation

duration

Содержание FJR1300

Страница 1: ...LIT 11616 16 18 5JW 28197 10 FJR1300R FJR1300RC SERVICE MANUAL ...

Страница 6: ......

Страница 82: ...2 22 SPEC TIGHTENING TORQUES Cylinder head tightening sequence Crankcase tightening sequence ...

Страница 89: ...2 29 SPEC 1 Crankshaft 2 Main axle 3 Drive axle OIL FLOW DIAGRAMS ...

Страница 90: ...2 30 SPEC 1 Oil nozzle 2 Main gallery bolt 3 Crankshaft OIL FLOW DIAGRAMS ...

Страница 91: ...2 31 SPEC 1 Main axle 2 Drive axle 3 Oil delivery pipe OIL FLOW DIAGRAMS ...

Страница 92: ...2 32 SPEC 1 Exhaust camshaft 2 Oil check bolt 3 Intake camshaft OIL FLOW DIAGRAMS ...

Страница 93: ...2 33 SPEC 1 Oil check bolt 2 Crankshaft 3 Oil cooler 4 Oil pump 5 Oil strainer 6 Oil pipe OIL FLOW DIAGRAMS ...

Страница 94: ...2 34 SPEC 1 Crank pin 2 Crankshaft OIL FLOW DIAGRAMS ...

Страница 95: ...2 35 SPEC 1 Rear balancer 2 Oil delivery pipe 3 Crankshaft 4 Front balancer 5 Crank pin OIL FLOW DIAGRAMS ...

Страница 97: ...2 37 SPEC 1 Main axle 2 Drive axle 3 Middle drive shaft OIL FLOW DIAGRAMS ...

Страница 98: ...2 38 SPEC COOLING SYSTEM DIAGRAMS 1 Radiator COOLING SYSTEM DIAGRAMS ...

Страница 99: ...2 39 SPEC 1 Water jacket joint 2 Oil cooler COOLING SYSTEM DIAGRAMS ...

Страница 100: ...2 40 SPEC 1 Thermostat assembly 2 Coolant reservoir 3 Radiator 4 Oil cooler COOLING SYSTEM DIAGRAMS ...

Страница 101: ...2 41 SPEC 1 Coolant reservoir 2 Radiator 3 Water pump COOLING SYSTEM DIAGRAMS ...

Страница 107: ...2 47 SPEC CABLE ROUTING 1 Tail brake light lead ...

Страница 196: ...3 80 CHK ADJ ADJUSTING THE HEADLIGHT BEAMS ...

Страница 288: ...4 92 CHAS 3 Install bearing 1 to the swingarm Installed depth a 4 0 mm 0 16 in SWINGARM ...

Страница 531: ...8 35 ELEC LIGHTING SYSTEM ...

Страница 570: ......

Страница 571: ...YAMAHA MOTOR CO LTD 2500 SHINGAI IWATA SHIZUOKA JAPAN PRINTED IN U S A ...