6. ENGINE REMOVAL; INSPECTION & INSTALLATION

6-52

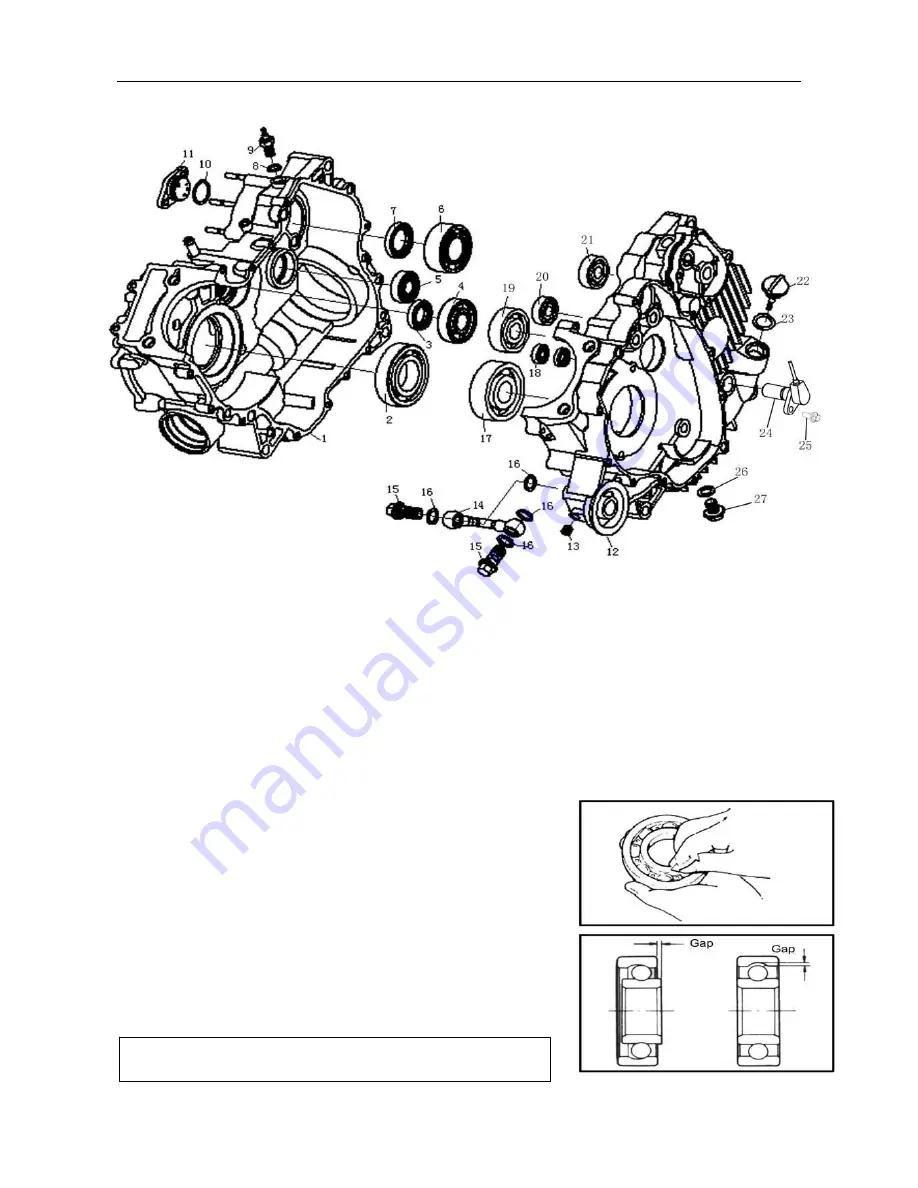

Crankcase

1. Right Crankcase 10. O-ring 19. Bearing

2. Bearing 11. Gear Sensor 20. Bearing

3. Oil Seal 12. Left Crankcase 21. Bearing

4. Bearing 13. Screw 22. Oil Dip Rod

5. Bearing 14. Oil Pipe 23. O-ring

6. Bearing 15. Link Bolt 24. Speed sensor

7. Oil Seal 16. Washer 25. Bolt

8. Washer, Reverse Gear Sensor 17. Bearing 26. Washer

9. Reverse Gear Sensor 18. Bearing 27. Oil Drainage Bolt

●

Clean and grease the bearings, turn the inner race

of bearing and check the play, noise and smooth

turning. In case of any abnormal, remove bearing

with special tool and replace;

●

Check all the oil seals for over wear or damage. In

case of any over wear or damage, remove with

special tool and replace with a new oil seal;

●

Remove gear sensor 11 and check for continuity

with reverse gear sensor 9 with a multimeter.

●

Remove link bolt and oil pipe 14 and check oil pipe

for crack or clog. Replace with a new one if any;

●

Remove oil drainage bolt 27 and clean it.

Note:

Check bearing for smooth turning after installation.

Содержание XY500UTV

Страница 1: ......

Страница 2: ...Service Manual XY500UTV XY500LUTV XY500UE XY500UEL 4 4 ZHEJIANG XINYANG INDUSTRY CO LTD ...

Страница 16: ...1 SERVICE INFORMATION 1 13 Cables Pipes Cable Routing 1 ...

Страница 17: ...1 SERVICE INFORMATION 1 14 ...

Страница 18: ...1 SERVICE INFORMATION 1 15 Carburetor Condition 1 ...

Страница 19: ...1 SERVICE INFORMATION 1 16 Carburetor Condition EFI Condition ...

Страница 20: ...1 SERVICE INFORMATION 1 17 Carburetor Condition 1 ...

Страница 21: ...1 SERVICE INFORMATION 1 18 ...

Страница 41: ...2 VEHICLE BODY MUFFLER 2 20 Description of visible parts ...

Страница 44: ......

Страница 66: ...4 COOLING AND LUBRICATIING SYSTEM 4 2 Cooling System Illustration 4 ...

Страница 114: ...6 ENGINE REMOVAL INSPECTION INSTALLATION 6 29 Primary and Secondary Sheave 6 ...

Страница 225: ......