MI-1071 20

In reassembly,

mount flywheel immediately after crank-

shaft is mounted; be sure woodruff key is in position

on shaft.

Do not

drive flywheel on to taper of crank-

shaft and

do not

overtighten flywheel nut. Simply turn

nut until lockwasher collapses. Then, after end play

is set,

(see End Play paragraph)

tighten flywheel nut

by placing wrench on nut and giving handle of wrench

1 or 2 sharp blows with a soft hammer. If torque

wrench is available, tighten

50 to 55 ft. lbs.

GEAR COVER (Fig’s. 29, 30 and 31)

Remove six capscrews holding gear cover in place and

drive out two

dowel pins

from crankcase side. Tap

gear cover with soft hammer at oil filler boss.

Caution:

Steel ball for crankshaft end thrust will probably fall

out when gear cover is removed. Take out thrust spring

from end of camshaft and remove flyweight assembly

from governor shaft.

In reassembly,

insert thrust spring into end of cam-

shaft and mount governor flyweight assembly. Lubricate

bearings, gear train and tappets.

Tap dowel pins into gear cover until they extend about

1/8” past the flange face. Place a dab of low melting

grease into hole of rear cover to retain camshaft

thrust spring ball in place. Lubricate lip of oil seal

and add a light film of oil to gear cover face to hold

gasket in place.

Place oil seal sleeve,

Fig 31

, on to crankshaft, drop

steel ball into grease filled hole and assemble gear

cover by tapping in place with a soft hammer.

Caution: Be sure timing marks on crankshaft and

camshaft gear, Fig. 38, remain correctly mated

when end of camshaft is pressed into bearing hole

of gear cover.

Note:

Governor lever must be leaning in a direction

toward the engine, as shown in

Fig. 30.

This position

will prevent the internal governor vane from becoming

entangled with the governor flyweights.

Remove oil seal sleeve, tighten gear cover capscrews

to

8 ft. lbs. torque

and hammer dowel pins in place.

CONNECTING ROD and PISTON (Fig’s 32, 33, 34)

By means of a 1/2” socket wrench, loosen and remove

connecting rod bolts, and take off connecting rod cap.

Scrape off all carbon deposits that might interfere with

removal of piston from upper end of cylinder. Turn

crankshaft until piston is at top, then push connect-

ing rod and piston assembly upward and out thru top

of cylinder.

The piston skirt is

cam-ground

to an elliptical con-

tour. Clearance between the piston and cylinder must

be measured at the bottom of the piston skirt thrust

face. Refer to Chart

, Fig. 33,

for proper clearance.

The thrust face on the piston skirt is 90° from the

axis of the piston pin hole.

In reassembly;

use a ring compressor and stagger the

piston ring gaps 90° apart around the piston. Oil the

piston, rings, wrist pin, rod bearings and cylinder

walls before assembly.

Note:

Mount piston and rod assembly with the cast

arrow

on the connecting rod bolt boss facing towards

the open end of the crankcase, and the

oil hole

in

Содержание Air Cooled TR-10D

Страница 6: ...MI 937 2 4 Fig 1 289860C TAKE OFF rear and LEFT HAND SIDE VIEW of ENGINE...

Страница 7: ...5 MI 938 2 FAN END front and RIGHT HAND SIDE VIEW of ENGINE...

Страница 8: ...MI 939 2 6 SECTIONAL VIEWS OF ENGINE...

Страница 28: ......

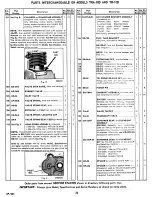

Страница 29: ...PARTS FOR ENGINE MODELS TRA 10D AND TR 10D...

Страница 30: ...PARTS FOR ENGINE MODELS TRA 10D AND TR 10D...

Страница 31: ...PARTS FOR ENGINE MODELS TRA 10D AND TR 10D...

Страница 32: ......

Страница 33: ......

Страница 34: ......

Страница 35: ......

Страница 36: ......

Страница 37: ......

Страница 38: ......

Страница 39: ......

Страница 40: ......

Страница 44: ......

Страница 46: ...WISCONSIN MOTOR CORPORATION MILWAUKEE WISCONSIN 532466 PRINTED IN U S A...