7 MI-1058

GENERAL DESIGN

Wisconsin

engines are of the

four cycle type

, in which

each of the four operations of

suction, compression,

expansion

and

exhaust

constitutes a complete stroke.

This gives one power stroke for each two revolutions of

the crankshaft.

COMPRESSION RELEASE

A component part of the camshaft that operates auto-

matically and trouble free. Permits fast and effortless

starting with no dangerous “kick back”.

COOLING

Cooling is accomplished from a flow of air circulated

over the cylinder and head of the engine, by a combi-

nation fan-flywheel encased in a sheet metal shroud.

The air is divided and directed by ducts and baffle

plates to insure uniform cooling of all parts.

Never operate an engine with any part of the

shrouding removed, because this will retard the

air cooling.

Keep the cylinder and head fins free from dirt

and chaff. Improper circulation of cooling air will

cause engine to overheat.

CARBURETOR

The proper combustible mixture of gasoline and air is

furnished by a balanced carburetor, giving correct fuel

to air ratios for all speeds and loads.

IGNITION

The spark for ignition of the fuel mixture is furnish-

ed by a high tension

flywheel magneto

. A stator plate

functions as an engine bearing plate as well as a sup-

port for the coil and core. The permanent magnet is an

integral part of the flywheel, and a breaker box on the

side of the crankcase contains the points, condenser

and stop switch. A push pin, actuated by the engine

camshaft, operates the

breaker arm at half engine speed

.

Battery ignition

(12 volt) can be furnished in place of

magneto, when specified. An ignition coil and breaker

assembly are the means of inducing high voltage to

the spark plug

. Battery is not

furnished by Wisconsin

Motor Corporation.

LUBRICATION SYSTEM

An oil dipper on the connecting rod provides for a

splash type lubrication system. The action of the dip-

per striking the oil in the crankcase provides ample lub-

rication for all internal parts of the engine.

GOVERNOR

A governor of the centrifugal flyball type controls the

engine speed by varying the throttle opening to suit

the load imposed upon the engine. Manually operated

variable speed controls are available for practically

all applications.

ROTATION

The rotation of the crankshaft is

clockwise

when

viewing the flywheel or starting end of the engine.

This gives

counter-clockwise

rotation at the power

take-off end of the crankshaft.

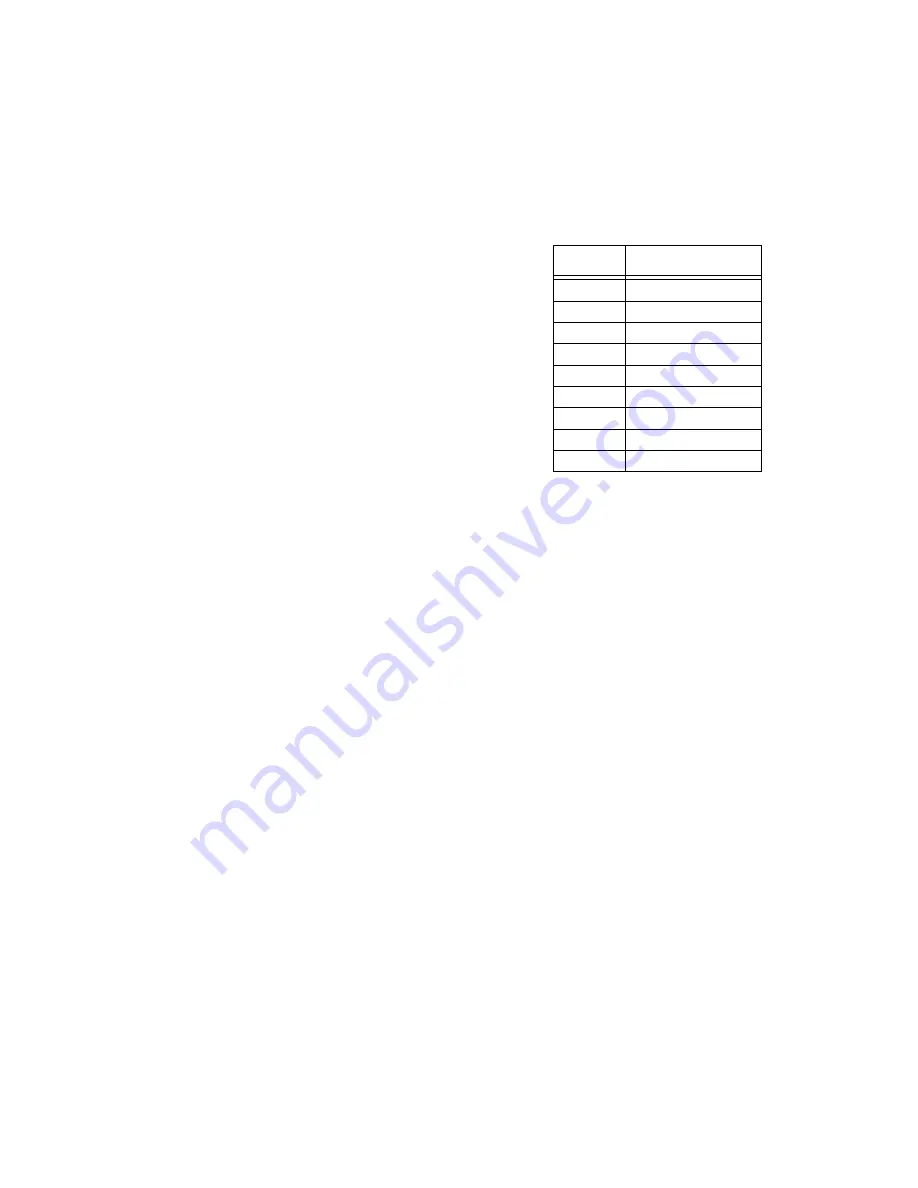

Horsepower

given in the accompanying chart is for an

atmospheric temperature of 60° Fahrenheit at sea

level and at a Barometric pressure of 29.92 inches of

mercury.

HORSEPOWER

For each inch lower the Barometric pressure drops,

there will be a loss in horsepower of 3

½

%.

For each 10° temperature rise there will be a reduce-

tion in horsepower of 1%.

For each 1000 ft. altitude above sea level there will

be a reduction in horsepower of 3

½

%.

The friction in new engines cannot be reduced to the

ultimate minimum during the regular block test, but

engines are guaranteed to develop at least 85 per

cent of maximum power when shipped from the fac-

tory. The power will increase as friction is reduced

during the first few days of operation. The engine will

develop at least 95% of maximum horsepower when

friction is reduced to a minimum.

INSTRUCTIONS FOR

STARTING AND OPERATING

LUBRICATION

Before starting a new engine, fill crankcase base with

the correct grade of engine oil, as specified in “

grade

of oil chart

”. Fill thru the dipstick plug opening illus-

trated in

Fig. 4

, with

1 quart

of oil.

For

run-in of new engines

, use same oil as recom-

mended in Grade Of Oil Chart.

The oil level mark is indicated by a groove on the dip

stick as shown in

Fig 4

. Check oil level by resting

the bottom of plug at the top of oil filler opening on

gear cover. (Do not thread in place to check level).

Too much emphasis cannot be given to the matter of

oil selection. High grade oil of the body suited to the

requirements of your engine is the most important sin-

gle item in the economical operation of the unit, yet

R.P.M

MODEL TRA-10D

2000

5.4

2200

6.1

2400

6.8

2600

7.6

2800

8.3

3000

8.8

3200

9.4

3400

9.8

3600

10.1

Содержание Air Cooled TR-10D

Страница 6: ...MI 937 2 4 Fig 1 289860C TAKE OFF rear and LEFT HAND SIDE VIEW of ENGINE...

Страница 7: ...5 MI 938 2 FAN END front and RIGHT HAND SIDE VIEW of ENGINE...

Страница 8: ...MI 939 2 6 SECTIONAL VIEWS OF ENGINE...

Страница 28: ......

Страница 29: ...PARTS FOR ENGINE MODELS TRA 10D AND TR 10D...

Страница 30: ...PARTS FOR ENGINE MODELS TRA 10D AND TR 10D...

Страница 31: ...PARTS FOR ENGINE MODELS TRA 10D AND TR 10D...

Страница 32: ......

Страница 33: ......

Страница 34: ......

Страница 35: ......

Страница 36: ......

Страница 37: ......

Страница 38: ......

Страница 39: ......

Страница 40: ......

Страница 44: ......

Страница 46: ...WISCONSIN MOTOR CORPORATION MILWAUKEE WISCONSIN 532466 PRINTED IN U S A...