MP-324-4 39

Order parts from nearest

SERVICE STATION

shown in directory falling parts list.

IMPORTANT:

Always give Model, Specification and Serial Numbers as shown on name plate

INSTRUCTIONS FOR MAINTENANCE AND REPAIR OF FUEL PUMP

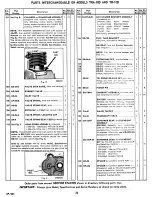

WISCONSIN MOTOR PART NO. ENGINE MODELS USED ON

LP-42-A

THD

LP-42-B

ACN, BKN, AENL

LP-42-G

AGND

LP-42-L

S-7D

LP-42-N

S-8D, TR-10D, TRA-10D

The efficiency of the fuel pump will gradually decrease

any time after 500 hours of operation. This will be

dictated by the engines faltering at high speeds or when

heavy loads are suddenly applied. The pump can easily be

restored to its normal efficiency by the installation of a

Wisconsin Motor No. LQ-28

repair kit.

1. Remove the fuel lines and the two mounting bolts

which hold the pump to the engine. Take the pump to a

work bench or suitable place.

2. With file, make an indicating mark across a point at the

union of castings (11 and 12). This is a positive loca-

tion of the fuel line positions when reassembling. Re-

move four assembly screws (15) and remove fuel head.

3. Turn head (12) over and remove one screw (16). Remove

(10, 3, 6 and 5) valve assemblies, noting their posi-

tions. Discard the above parts (3, 6 and 5).

4. Clean fuel head thoroughly with gasoline and a fine

wire brush.

5. Holding fuel head, (12) with diaphragm surface (con-

taining four clearance holes) up, reassemble the valve

spring (3) and valve (6) into cavity from which they

were removed. Now place new gasket (5) in position and

reassemble the valve retainer (10) into position and

lock it by inserting and tightening the fuel pump valve

retainer screw (16).

6. Place this fuel pump head assembly in a clean place and we

are ready to rebuild the lower diaphragm section.

7. Using a screw driver, inserted into the coils of rocker

arm spring (13), remove this spring and save.

8. Holding the mounting bracket (11) in the left hand

with the rocker arm toward the body and the thumb nail on

the end of the link (9) with the heel of the right hand

on the diaphragm (2) compress the diaphragm spring (4)

at the same time, turning in a clockwise position 90°.

This will unhook the diaphragm from the link (9) so it

can be removed.

9. Clean the mounting bracket (11) with gasoline and fine

wire brush.

10. Replace the new diaphragm operating spring (4), stand-

ing it into casting (11). Repeat in reverse step eight,

using the new diaphragm. Replace rocker arm spring

removed in step seven.

11. Mount this assembly back on the engine in the position

from which it was removed, using the new mounting

gasket which is the last piece of the repair kit.

12. Crank the engine over to a position where the dia-

phragm (2) is laying flat on the mounting bracket (11).

Place the fuel head (12) back in position so that the

indicating marks of step one are in line, and start the

four assembly screws approximately three turns. Again,

crank the engine over to a position where the diaphragm

(2) is pulled down into (11) mounting bracket and tight-

en the four assembly screws (15) tightly.

13. Connect the fuel lines and you have a completely re-

built fuel pump.

NOTE:

The

LQ-28 Repair Kit

and the parts included there-in,

which are identified by an asterisk (*), are the only parts

of the fuel pump available for service.

Ref

No

Description

No

Req

1

* 2

* 3

* 4

* 5

* 6

7

8

9

10

11

12

13

15

16

*

ROCKER ARM

.............................................

DIAPHRAGM

..............................................

VALVE SPRING

............................................

DIAPHRAGM SPRING

..................................

VALVE GASKET

...........................................

VALVE

.........................................................

ROCKER ARM PIN

.......................................

SPRING CLIP

for rocker arm .......................

LINKAGE

.....................................................

VALVE PLATE

and

SEATS.

...........................

MOUNTING BRACKET

................................

HEAD

..........................................................

ROCKER ARM SPRING

................................

ASSEM. SCREW

and

LOCKWASHER

............

VALVE PLATE SCREW

and

LOCKWASHER

...

MOUNTING FLANGE GASKET

(not illustrated)

1

1

2

1

1

2

1

1

1

1

1

1

1

4

1

1

Содержание Air Cooled TR-10D

Страница 6: ...MI 937 2 4 Fig 1 289860C TAKE OFF rear and LEFT HAND SIDE VIEW of ENGINE...

Страница 7: ...5 MI 938 2 FAN END front and RIGHT HAND SIDE VIEW of ENGINE...

Страница 8: ...MI 939 2 6 SECTIONAL VIEWS OF ENGINE...

Страница 28: ......

Страница 29: ...PARTS FOR ENGINE MODELS TRA 10D AND TR 10D...

Страница 30: ...PARTS FOR ENGINE MODELS TRA 10D AND TR 10D...

Страница 31: ...PARTS FOR ENGINE MODELS TRA 10D AND TR 10D...

Страница 32: ......

Страница 33: ......

Страница 34: ......

Страница 35: ......

Страница 36: ......

Страница 37: ......

Страница 38: ......

Страница 39: ......

Страница 40: ......

Страница 44: ......

Страница 46: ...WISCONSIN MOTOR CORPORATION MILWAUKEE WISCONSIN 532466 PRINTED IN U S A...