14

Westward Operating Instructions and Parts Manual 1KEN3, 1KEN4

10”,12” Drill Presses

Operation

Basic drill press operation

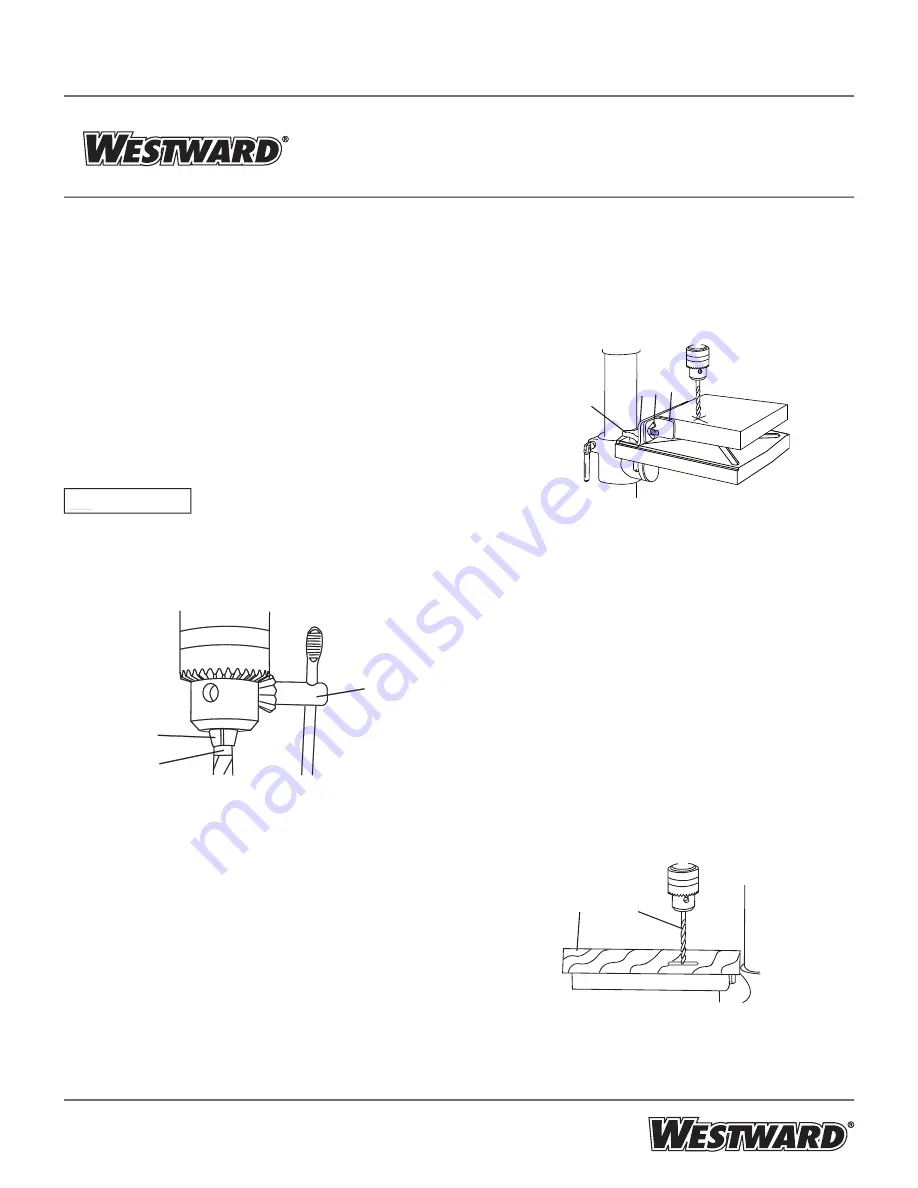

Installing drill bit in chuck (Figure 23)

1. With the switch “OFF” and the switch key removed,

open the chuck jaws (1) using the chuck key (2).

Turn the chuck key counterclockwise to open the

chuck jaws (1).

2. Insert the drill bit (3) into the chuck far enough to

obtain maximum gripping by the jaws, but not far

enough to touch the spiral grooves (fl utes) of the drill

bit when the jaws are tightened.

3. Make sure that the drill is centered in the chuck.

4. Turn the chuck key clockwise to tighten the jaws.

To avoid injury or accident by the

chuck key ejecting forcibly from the chuck when the

power is turned “ON”, use only the self-ejecting chuck

key supplied with this drill press. ALWAYS recheck and

remove the chuck key before turning the power “ON”.

Figure 23

Using the fence (Figure 24) (The fence assembly has been

supplied for 12” drill press only.)

The fence provides a way of accurately and quickly

setting up the workpiece for precision or for repitive

drilling operations.

1. Using a centerpunch or sharp nail, make an

indentation in the workpiece where you want to drill.

2. Align the laser lines (x) with the indentation on the

workpiece.

3. Loosen the knobs (1) and slide the fence back stop (2)

fi rmly against the long side of the workpiece. Tighten the

knobs when in position.

4. Loosen the wing nut (3) and slide the end stop (4)

along the fence until it is fi rmly against the left side of the

workpiece. Tighten the wing nut.

5. Check the accuracy by drilling into a scrap workpiece

fi rst. Adjust if needed.

6. Hold with your hand or clamp the top surface of the

workpiece fi rmly to prevent it from lifting off the table when

the bit is raised.

Figure 24

Drilling to a specifi c depth

Drilling a blind hole (not all the way through workpiece) to a

given depth can be done two ways:

Workpiece method (Figure 25 and Figure 26)

1. Mark the depth (1) of the hole on the side of the workpiece

(Figure 25 ).

2. With the switch “OFF”, bring the drill bit (2) down until the

tip is even with the mark (Figure 25).

3. Hold the feed handle at this position.

4. Spin the lower nut (3) down to contact the depth stop lug

(6) on the head (Figure 26).

5. Spin the upper nut (5) down and tighten against the lower

nut (3) (Figure 26).

6. The drill bit will now stop after traveling the distance

marked on the workpiece.

Figure 25

WARNING

!

1

3

2

1

2 33 44

2

1