Part number 550-100-305/0118

49

AquaBalance

TM

W

ALL

M

OUNT

GAS

-

FIRED

WATER

BOILER

—

Boiler Manual

20

Gas piping

(continued)

Gas pipe sizing

1. See page 16 for gas line sizing information.

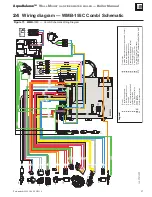

Check gas pressure at inlet to boiler

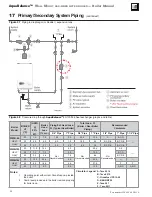

1. See Figure 60 for location of the gas inlet pressure test port.

Check the operational (working) gas inlet

pressure

1. Set up the boiler to operate at maximum rate as described in

section “ Test mode” Figure 99, page 74.

2. With the boiler operating at maximum rate check that the op-

erational (working) gas pressure at the inlet gas pressure test

port (see above) complies with the requirements of Table 2 .

3. Ensure that this inlet pressure can be obtained with all other

gas appliances in the property working.

Measure the gas rate

Measure the gas rate and check against following Table 2:

For natural gas or liquefied petroleum (propane) gas, the pres-

sure required at gas valve inlet pressure port (verify minimum

gas pressure when all gas appliances are in operation):

a. Maximum: 13” w.c. with no flow (lockup) or with boiler

on.

b. Minimum: 3.5” w.c. gas pressure, with gas flowing (verify

during boiler startup, while boiler is at high fire)

c. Nominal gas pressure: 11.0” w.c.

4. Install 100% lockup gas pressure regulator in supply

line if inlet pressure can exceed 13” w.c. at any time.

Adjust lockup regulator for 13” w.c. maximum.

Figure 60

Inlet test port on gas valve

Inlet test port

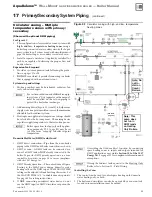

Gas Rate

(Natural Gas)

After 10 minutes from cold

Combi

Boiler

model

Maximum rate

Minimum rate

ft

3

/h

ft

3

/h

WMB-80

78.4

7.8

WMB-120

117.6

11.8

WMB-155

151.9

15.2

Table 2

Gas rate for Combi and Heating Only boilers