SPECIFICATIONS

ACCESSORIES

MOTOR

2HP

ELLIPTICAL

JIG

EJ

‐

92

RPM

6900

FEED

RATE

0

‐

19FPM

CRANK

EXTENSION

54

‐

306

MAX

PROFILE

DEPTH

¾”

MAX

PROFILE

WIDTH

6

¾”

PLANING

WIDTH

7”

MIN

STOCK

LENGTH

9”

MIN

STOCK

THICKNESS

¼”

MAX

STOCK

THICKNESS

8”

WORKING

HEIGHT

35”

OVERALL

HEIGHT

50”

OVERALL

WIDTH

22”

OVERALL

LENGTH

28”

SHIPPING

WEIGHT

260#

SAFETY RULES

Your

W&H

Molder

has

been

designed

for

maximum

safety,

however,

as

with

all

power

tools;

there

is

a

possibility

of

incident

or

injury

to

the

operator.

Therefore,

it

is

impera ve

that

this

manual

is

completely

read

and

understood

before

using

.

Use

your

W&H

Molder

with

respect

and

cau on.

Following

stated

and

inherent

safety

precau ons

will

considerably

lessen

the

possibility

of

personal

injury.

If

normal

safety

measures

are

not

taken

or

are

overlooked,

the

possibility

of

incident

rises

tremen

‐

dously.

These

safety

measures

are

simple

to

follow,

and

the

injuries

that

could

happen

are

not

worth

the

few

minutes

saved

by

ignoring

safety.

The

W&H

Molder

was

designed

for

speci

fi

c

applica ons.

Do

not

modify

or

use

the

machine

for

any

purpose

other

than

what

this

manual

describes

as

its

capabili es.

Subs tu ng

a

motor

with

a

horsepower

ra ng

over

2HP

cons tutes

a

modi

fi

ca on.

Any

modi

‐

fi

ca ons

or

improper

use

to

the

Molder

‐

Planer

may

result

in

personal

injury,

and

will

void

the

warranty.

Please

contact

us

if

you

are

unsure

about

safety

protocol

before

using

the

machine.

Содержание 20210492060001

Страница 19: ...ARBOR REMOVAL VIEW...

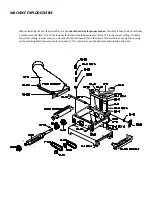

Страница 20: ...Stand exploded diagram...

Страница 22: ...Notes Maintenance Records...