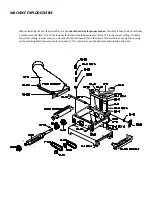

MACHINE

EXPLODEDVIEW

When

reinstalling

the

vari

‐

feed

unit

a er

a

repair

check the chains

for

proper tension

.

The

short

in

feed

chain

should

have

a

small

amount

of

slack

in

it

and

the

long

out

feed

chain

should

have

plenty

of

slack.

This

is

the

correct

se ng.

To

obtain

the

correct

se ng,

in

most

cases,

you

would

push

the

unit

toward

the

in

‐

feed

end

of

the

machine

as

you

ghten

it

using

up

the

a aching

bolt

hole

clearance

for

adjustment.

This

should

give

you

the

op mum

chain

tension

and

slack.

Содержание 20210492060001

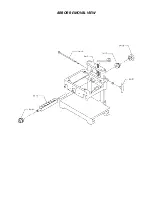

Страница 19: ...ARBOR REMOVAL VIEW...

Страница 20: ...Stand exploded diagram...

Страница 22: ...Notes Maintenance Records...