49

Finish 270 / 250

GB

repaIrs at the unIt

10.10

ReMedy In cASe OF FAultS

type of malfunctIon what else?

possIble cause

measures for elImInatIng the malfunctIon

Unit does not start

Motor switch can not

switched on

No voltage applied

Check voltage supply

Unit fuse has triggered

Let the motor cool down

Unit does not suck in

Air bubbles exit from

the return hose

Unit is sucking in outside

air

Check: Suction system tightened properly?

Cleaning connection at rigid suction tube

screwed tight and not leaking? Inlet valve

button leaky? -> Replace wiper and O-ring (->

refer to Section 10.1)

Air bubbles do not exit

at the return hose

Inlet valve clogged

Press the inlet valve button until the stop is

reached several times by hand

Inlet/outlet valve soiled

/ foreign bodies (e.g.

threads) drawn in / worn

Remove the valves and clean then (-> refer to

Section Pkt.10.2/10.3) / replace worn parts

Pressure control valve tur-

ned down completely

Turn the pressure control valve to the right un-

til the stop is reached

Unit does not gene-

rate pressure

Unit has sucked in

Air in the oil circuit

Bleed the oil circuit in the unit by turning the

pressure control valve completely to the left

(until overturning) and let it run approx. 2 – 3

min. Then turn the pressure control valve to

the right and set the spraying pressure (repeat

process several times, if necessary). Process is

assisted by positioning the unit vertically.

Unit reached pressu-

re, but the pressure

collapses, also at the

pressure gage, during

spraying.

Suction filter clogged

Check the suction filter. If necessary, clean/

replace

Paint cannot be worked in

this state. Due to its pro-

perties the paint clogs the

valves (inlet valve) and the

delivery rate is too low.

Dilute the paint

Unit reached pressure,

but the pressure col-

lapses during spraying.

pressure gage still

shows high pressure

Clogged filter do not let

enough paint pass

Check/clean the (high-pressure filter) gun filter

Tip clogged

Clean the tip (-> refer to Section 10.1)

Unit does not generate

the max. pressure pos-

sible. Paint neverthe-

less exits at the return

hose.

Relief valve defective

Clean or replace the relief valve (-> refer to

Section 10.5)

Содержание Finish 250

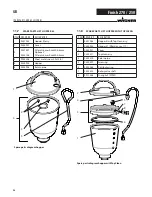

Страница 19: ...19 Finish 270 250 10 9 Schaltplan d reparaturen am ger t...

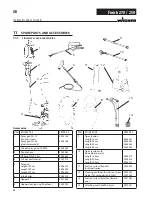

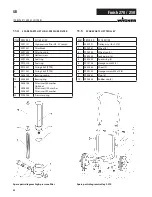

Страница 24: ...24 Finish 270 250 ersatzteile und zubeh r Ersatzteilbild Pumpenaggregat d...

Страница 48: ...48 Finish 270 250 GB Repairs at the unit 10 9 Connection diagram...

Страница 53: ...53 Finish 270 250 GB Spare parts diagram pump aggregate Spare parts and accessories...

Страница 77: ...77 Finish 270 250 10 9 Sch ma lectrique F R parations sur l appareil...

Страница 83: ...83 Finish 270 250 Illustration des pi ces de rechange du groupe de pompage pi ces de rechange et Accessoires F...

Страница 107: ...107 Finish 270 250 10 9 Elektrisch schema Reparaties aan het apparaat NL...

Страница 112: ...112 Finish 270 250 Onderdelenafbeelding pompaggregaat NL Accessoires en onderdelen...

Страница 118: ...118 Finish 270 250 NL CE Verklaring van overeenstemming...

Страница 119: ...119 Finish 270 250 NL CE Verklaring van overeenstemming...