Route the discharge pipe in accordance with EN 12828 into a drain

outlet (drain outlet kit available as an accessory). The drain outlet

incorporates a siphon as a stench trap.

Low water indicator

According to EN 12828, a low water indicator can be omitted for boil-

ers up to 300 kW, as long as heating can be reliably prevented when

there is a water shortage.

Viessmann condensing boilers are equipped with a low water indica-

tor (boil-dry protection). Tests have verified that the burner will be

automatically switched off in the event of water shortage due to a

leak in the heating system and simultaneous burner operation,

before the boiler or the flue system reaches unacceptably high tem-

peratures.

Water quality/frost protection

Unsuitable fill and top-up water increases the level of deposits and

corrosion and may lead to boiler damage.

Observe VDI guideline 2035 regarding the quality and volume of

heating water, incl. fill and top-up water.

CH: Observe SWKI guideline BT 102-01.

■ Flush the heating system thoroughly before filling.

■ Only fill with water of potable quality.

■ VDI guideline 2035 recommends water softening treatment to pre-

vent harmful scaling in the heating water. Additives to stabilise

hardness do not remove the scale forming chemicals from the

heating water. Fill and top-up water with a water hardness in

excess of the following values must be softened, e.g. with the

small softening system for heating water (see the Viessmann

Vitoset pricelist):

Total permissible hardness of the fill and top-up water

Total heating

output

Specific system volume

kW

< 20 l/kW

≥ 20 l/kW to

< 50 l/kW

≥ 50 l/kW

≤ 50

≤ 3.0 mol/m

3

(16.8 °dH)

≤ 2.0 mol/m

3

(11.2 °dH)

< 0.02 mol/m

3

(0.11 °dH)

> 50 to ≤ 200

≤ 2.0 mol/m

3

(11.2 °dH)

≤ 1.5 mol/m

3

(8.4 °dH)

< 0.02 mol/m

3

(0.11 °dH)

■ For systems with a specific system volume in excess of 20 l/kW

heating output, use the output of the smallest boiler in multi boiler

systems.

■ Special antifreeze (category 1 to 3) suitable for heating systems

can be added to the fill water. The use of glycols without sufficient

inhibition and buffering is not permitted. The suitability of the anti-

freeze must be confirmed by the manufacturer. If antifreeze is

added, more monitoring and maintenance is necessary. Observe

the manufacturer's instructions. Viessmann accepts no liability for

damage and malfunctions caused by unsuitable or incorrectly

dosed antifreeze, or incorrect maintenance.

■ EN 1717 and DIN 1988-100 must be observed if the heating water

is used simultaneously as a heat transfer medium for DHW heat-

ing.

■ When disposing of heating water that contains additives, check

whether it may be discharged into the public drain network once it

has been treated again.

When designing the system, observe the following:

■ Install shut-off valves in each section. This prevents the need for

draining all the heating water in the case of repairs or system

expansion.

■ In systems > 50 kW, install a water meter to record the volume of

fill and top-up water. Record the amount of water filled into the sys-

tem and the water hardness.

Operating information:

■ Commission the system step by step, starting with the lowest

boiler output and a high heating water flow rate. This prevents

localised concentration of limescale deposits on the heating surfa-

ces.

■ In multi boiler systems, start all boilers simultaneously to prevent

the total amount of limescale deposits settling in the heat

exchanger of just one boiler.

■ During expansion or repair work, only drain the necessary pipe-

work sections.

■ Where water treatment is required, treat even the first fill of the

heating system prior to commissioning. This also applies to any

subsequent filling, e.g. when adding top-up water or after a repair,

or for any system expansion.

■ Check, clean and activate filters, dirt traps and other blow down or

separating facilities in the heating water circuit more frequently

after commissioning and in new installations. Later on this can be

carried out subject to the requirements of the water treatment

applied (e.g. water softening).

Installation examples

For installation examples, see "www.viessmann-schemes.com".

Never install the Vitodens 222-W in dual mode systems with solid

fuel boilers.

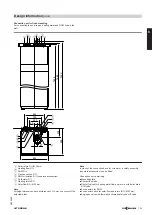

Expansion vessels

In accordance with EN 12828, water heating systems must be equip-

ped with an expansion vessel.

An expansion vessel is integrated in the boilers:

■ Vitodens 200-W and 222-W: Capacity 10 l

■ Vitodens 222-F and 242-F: Capacity 18 l

Pre-charge pressure in the delivered condition: 0.75 bar (0.075 MPa)

Determine the size of the expansion vessel to be installed in accord-

ance with EN 12828.

If the integral expansion vessel is insufficient, install a suitably sized

expansion vessel on site.

Note

When hydraulically connecting the diaphragm expansion vessel,

ensure that there is always a connection between the diaphragm

expansion vessel and the heat generator.

For example, when the thermostat valves are closed and if the 3-

way diverter valve is set to "DHW". The 3-way diverter valve is

installed in the heating water flow.

Design information

(cont.)

VITODENS

VIESMANN

135

5853906

8

Содержание Vitodens 200-W B2HE

Страница 154: ...154 VIESMANN VITODENS...

Страница 155: ...VITODENS VIESMANN 155 5853906...