22

1. Manual operation

For the boiler ignition it is necessary to operate manually the fuel

conveyor and ventilator. For this purpose there serve the pushbuttons

1

and

2

. Pushbutton

1

operates the ventilator, pushbutton

2

the fuel

conveyor. By pressing the relevant unit is switched on and by repeated

pressing the relevant unit is switched off. The ventilator operation is

displayed by burning line(stroke) under the ventilator symbol. Once the

ventilator stops the line goes out. The same applies to the fuel conveyor operation indication. It is indicated

by a line(stroke) under the fuel symbol. The fact that the boiler is manually operated is indicated on display

by abbreviation

ru

and burning stroke at the notice

„manual“.

2. Fuel conveyor cycles setting

For a correct boilers function it is necessary to set an optimal proportion between

the time for fuel

feeding

(conveyor works) and the

time for

fuel afterburning

(conveyor in resting stage)

a) By pressing the pushbutton

4

there appears on display the data like

on

15

and it means the operation of fuel reservoir screw conveyor

15

(combustion chamber screw conveyor works parallel, but incl. after-

running). The value can be changed by pressing the pushbutton

*

and

entering a new digit combination like

20

. Then

oF 20

is alight on

display

.

The decision correctness must be confirmed by pushbutton

*

.

Confirmation

o.k.

must appear on display

.

The fuel feeding time can be set within

3 - 90

s, see tab. no.5.

b) By pressing the pushbutton

5

there appears on display the data like

oF

20

and it means that the conveyor is in a resting state for

20

s. The

value can be changed by pressing the pushbutton

*

and entering a

new digit combination like

30

. Then

oF 30

is alight on display

.

The

decision correctness must be confirmed by pushbutton

*

. Confirmation

o.k.

must appear on display

.

The after-combustion time can be set within

3 - 90

s, see tab. no.5.

3. Inhibition duration setting

If the heating water outlet temperature has exceeded the set limit the regulator will shut down the fuel

feeder and ventilator until the temperature drops below the set limit with hysteresis -3 °C. It could happen

that this time is too long and the boiler burns out. That’s why there is set the maximum shut down time so

called.

inhibition duration.

Once it has passed over the ventilator and fuel conveyor start up automatically

within 2 minutes, independently on heating water outlet temperature. Then the regulator comes back into

inhibition status and follows the heating water outlet temperature. The circulating pump is constantly

switched on. The same can be induced by indoor thermostat once the room temperature has been

exceeded. Then besides the induction into the inhibition status there is switched off the circulating pump

while keeping the 4 minutes after-running.

By pressing the pushbutton

6

there appears on display the data like

Ut 20

and it means the

20

minutes

inhibition duration. The value can be changed by pressing the

pushbutton

*

and entering a new digit combination like

30

. Then

oF 30

is

alight on display

.

The decision correctness must be confirmed by

pushbutton

*

. Confirmation

o.k.

must appear on display

.

The inhibition

duration can be set between

5 and 90

minutes. Recommended value is

30

min. If in this regime the heating water temperature significantly rises

(first of all in summer season, when there is a minimum heat take-off

from the system), it is recommended to increase this value.

Inhibition on display is indicated by a burning point in its right lower

corner.

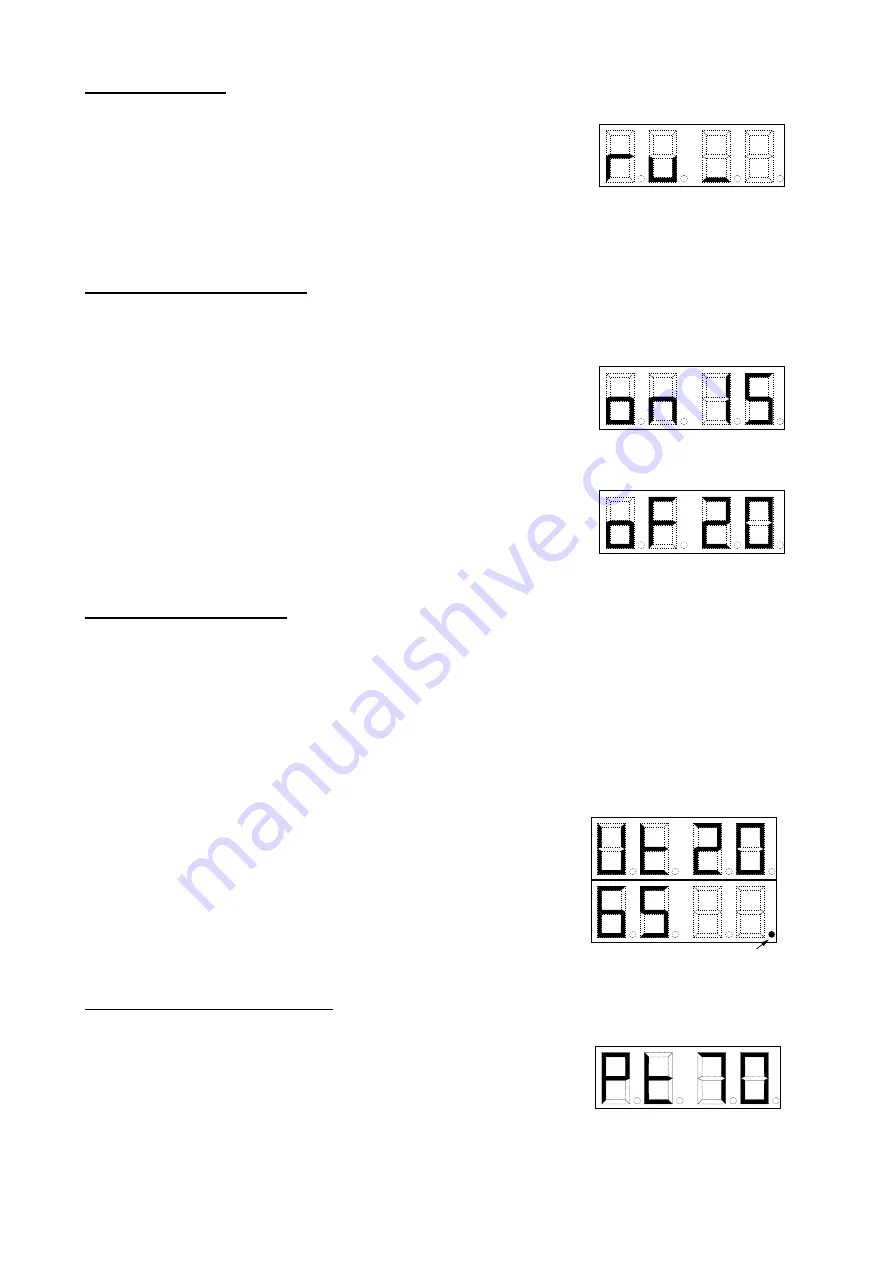

4. Outlet water temperature setting

The required outlet water temperature

is set by means of pushbutton

3

. On display there appears the

data like

Pt 70

and it means the required outlet water temperature of

70

°C. The value can be changed by pressing the pushbutton

*

and entering

a new digit combination like

75

. Then

Pt 75

is alight on display. The

decision correctness must be confirmed by pushbutton

*

. Confirmation

o.k.

must appear on display

.

The required outlet water temperature can

be set between

60 and 90

°C. It is recommended to operate boiler at temperatures higher than

65

°C.

Indikace útlumu

Inhibition