Before making the jaws and installing the vise, you will

need to consider the following:

• Which end of the workbench: generally, a right-

handed woodworker will install the front vise on

the left-hand end of the workbench (as shown in

the diagrams in these instructions). This keeps the

mechanism out of the way when planing long boards

clamped against the front of the workbench (i.e.,

when jointing an edge). A left-handed user would

usually want the front vise on the right-hand end of

the workbench.

• Size of the front jaws: the mechanism of the vise has

been designed around a nominal jaw width of 18

1

/

2

"

.

Wider is possible if required; however, a jaw wider

than 24

"

will begin to put higher-than-anticipated

side loads on the vise.

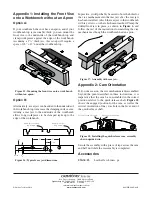

• Dog holes: the front jaw should be thick enough to

allow for dog holes so that the vise can be used to

clamp parts to the top of the workbench. Ideally,

these holes should align to the dog-hole matrix in the

workbench top. The holes also need to be located so

that they do not interfere with holes for the various

rods and screws the mechanism will require (see

Figure 4

).

• Jaw thickness: this vise was designed around a 1

3

/

4

"

thick front jaw and a 2

"

thick apron. A 1

3

/

4

"

thick

front jaw in a suitable hardwood will give sufficient

strength and can easily accommodate

3

/

4

"

diameter

dog holes.

• Relative mechanism position: generally, it is desirable to

offset the mechanism in the jaw to give a larger clear space

on one side of the mechanism for through clamping.

Depending on the overall workbench design, there may be

other critical elements to consider. Judicious planning will

go a long way towards making the installation go smoothly.

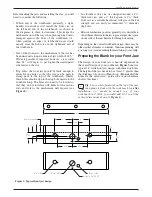

Preparing the Blank for your Front Jaw

The design of your front jaw is heavily dependent on

the overall design of your workbench.

Figure 3

shows a

typical 18

"

wide front jaw design with three dog holes.

The height of the jaw needs to be at least 3

"

greater than

the thickness of your workbench top. (

Do not

drill the

holes for the main screw, guide rods or quick-release

shaft at this time.)

...

Tip:

Leave a bit of material on the top of the jaw,

then plane it fl ush with the workbench top

after

installation;

1

/

32

" should be enough (e.g., if your

workbench is 2" thick, you would add 2

1

/

32

" to all the

vertical dimensions shown in

Figure 3

).

Figure 3: Typical front jaw design.

3

Veritas

®

Quick-Release Front Vise

Bench Thickness

3

/

4

"

7

/

8

"

5

"

5

"

1

1

/

8

"

4

1

/

4

"

2

1

/

2

"

Ø 1

1

/

2

"

THRU

Ø

3

/

4

"

THRU

Ø

7

/

32

"

× 1

1

/

4

"

DEEP

Ø 1

"

THRU

1

13

/

16

"

1

11

/

16

"

4

1

/

4

"

18

"