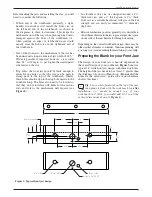

Four mounting holes are required to attach the vise

mechanism to the underside of the workbench top.

Figure 8

shows the dimensional locations for the mounting holes

relative to the center line of the main screw, or you can

use the

Mounting Hole Template

(included).

Note:

Do not

use the base casting to transfer the hole

locations; these holes are too large to provide an

accurate transfer.

Figure 8: Mounting hole locations.

The two front holes require

5

/

8

"

diameter by

1

/

4

"

deep

counterbores. The four mounting screws require

5

/

16

"

diameter by 1

1

/

2

"

deep pilot holes, if the workbench

is hardwood (

9

/

32

"

diameter by 1

1

/

2

"

deep pilot holes

in softwood).

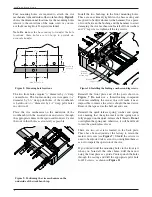

Place the vise mechanism on the underside of the

workbench with the assorted rods and screws through

the appropriate holes in the apron and front jaw. Center

the rods in their holes as accurately as possible.

Figure 9: Positioning the vise mechanism on the

underside of the workbench top.

Install the two bushings in the front mounting holes.

These are an extremely tight fi t in the base casting and

may need to be driven home with a hammer. Use a piece

of wood between the bushing and the hammer to avoid

damaging the vise mechanism. Install all four washers

and

3

/

8

"

lag screws; tighten all the lag screws.

Figure 10: Installing the bushings, washers and lag screws.

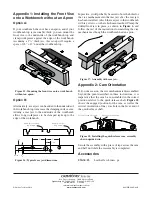

Reinstall the front plate and all the parts shown in

Figure 7

.

Do not

use a thread-locking compound

when reassembling the vise as this will make it near-

impossible to remove the screws should the need arise.

Remove the tape across the half nut and cam.

Reinstall the quick-release spring, washer and spring

nut, ensuring that the nylon insert in the spring nut is

fully engaged on the quick-release shaft threads.

Do not

overtighten the spring nut; otherwise, it will be diffi cult

to turn the quick-release lever.

There are two set screws located in the back plate.

These have been adjusted at the factory to retain the

main screw cover (see

Figure 7

). Should the set screws

need to be adjusted, take care not to overtighten them so

as not to impair the operation of the vise.

If you did not drill the mounting holes in the front jaw

when you bored all the other holes, drill them now

using the front plate as a guide. Center-punch the holes

through the casting and drill the appropriate pilot hole

for #14 screws, as shown in

Figure 11

.

15

/

16

"

8

3

/

16

"

4

3

/

32

"

4

3

/

32

"

3

9

/

16

"

Main Screw Axis

Back Edge

of Apron

Bushing

on front

screws only.

Washer

Lag Screw

6

Veritas

®

Quick-Release Front Vise