Positioning the Vise Mechanism

Clamp the jaw blank to your workbench in the position

you want the jaw to be. Place the vise mechanism on the

top of the workbench, aligning the main screw where

you want it to eventually be in relation to the jaw.

Jaw Blank

Main Screw

Figure 4: Positioning the jaw blank and vise

mechanism.

Place a square on each side of the main screw and

transfer the main screw location to the front of the jaw

using a pencil or marking knife. The main screw center

is between these two lines.

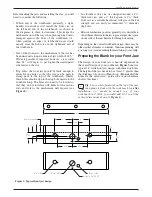

Preparing the Jaw

Unclamp the jaw and lay out the exact position of the

main screw hole, as shown in

Figure 3

. Keep in mind

that the jaw is slightly taller than its fi nal size.

Lay out the rest of the jaw holes using the

Jaw Hole

Template (

included), or as per the dimensions in

Figure 3

.

The horizontal hole locations are given from the location

of the main screw.

The through-hole sizes are minimum diameter; larger

holes will not adversely affect the action of the vise.

The 1

1

/

4

"

deep holes are for the #14 × 2

"

jaw mounting

screws. The

7

/

32

"

diameter hole shown is for a hardwood

jaw; use a

3

/

16

"

diameter hole if you are installing a

softwood jaw.

...

Tip:

It may be easier to drill the holes for the

mounting screws later in the installation process.

Note:

A drill press is recommended for boring these

holes to ensure they are bored square to the jaw face.

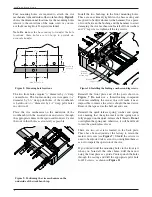

...

Tip:

When drilling the holes for the main screw,

guide rods, etc.,

do not

rotate or turn the workpiece

on the drill-press table. (See

Figure 5

.) Instead, slide

the workpiece over. If your drill press is slightly out of

alignment (off 90° from table to spindle), you will double

the error by turning your workpiece end for end rather

than sliding it along the drill-press table.

✔ ✗

Correct:

Slide workpiece

across table.

Workpiece

Table

Holes off but parallel.

Holes out of parallel.

Incorrect:

Do not

turn workpiece

end for end.

(Exaggerated views.)

Figure 5: Drilling the holes in the jaw.

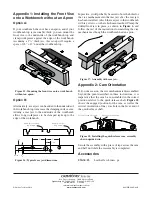

Drilling the Apron

Clamp the drilled front jaw to the workbench in the position

you want the jaw to be (see

Figure 6

). Keep in mind that

the top of the jaw is proud of the workbench top.

Use the holes in the jaw as drill guides for drilling out the

matching holes in the apron. Take care that the apron holes

are drilled square to the apron face.

Drill holes through

apron using holes in

jaw as drilling guide.

Figure 6: Drilling the apron.

Leave the jaw clamped in place for the rest of the

assembly process.

4

Veritas

®

Quick-Release Front Vise