Introduction

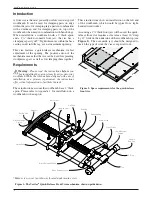

A front vise is the most generally useful vise on a typical

workbench. It can be used for clamping parts on edge

within the jaws, for clamping large parts in combination

with a deadman, and for clamping parts on top of the

workbench when used in combination with bench dogs.

When installed on a workbench with a 2

"

thick apron

and a 1

3

/

4

"

thick user-made front jaw, the vise has a

clamping capacity of 9

"

. Tight tolerances within the base

casting result in little sag, even at maximum opening.

This vise features a quick-release mechanism for fast

adjustment of the opening. The positive action of the

mechanism means that the vise can be used for spreading

workpieces apart, as well as for clamping them together.

Requirements

Warning:

Please read the instructions

before

you

begin installing the quick-release front vise onto your

workbench. While the vise has been designed with ease of

installation as a primary requirement, the instructions

offer critical information to facilitate the task.

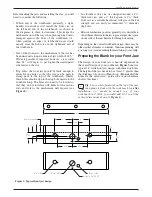

These instructions assume the workbench has a 2

"

thick

apron. Please refer to

Appendix 1

for installation on a

workbench with no apron.

These instructions show an installation on the left end

of the workbench, which would be typical for a right-

handed woodworker.

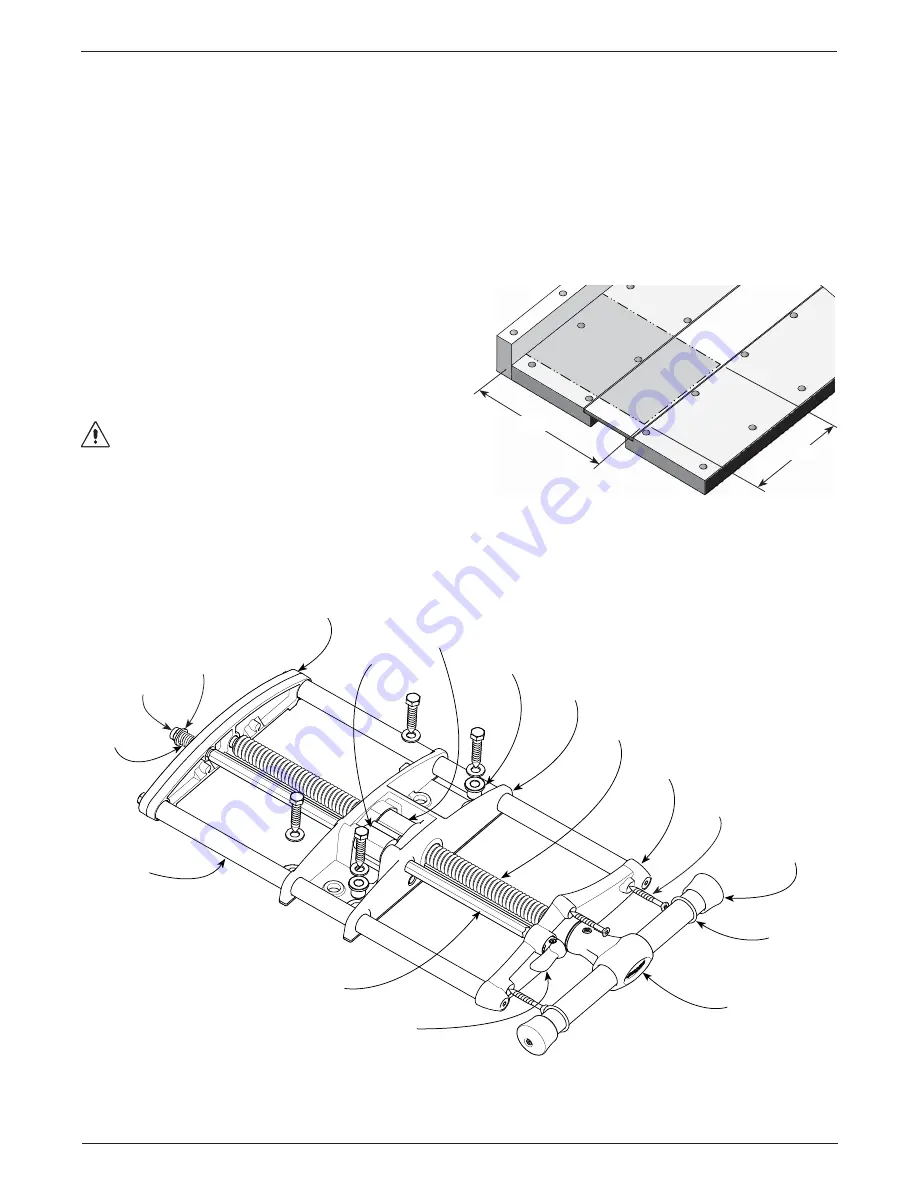

Assuming a 1

3

/

4

"

thick front jaw will be used, the quick-

release front vise requires a clear area at least 16

"

deep

by 12

"

wide on the underside of the workbench top (see

Figure 2

). The user-made jaw should be designed to

match the type of work the vise is expected to do.

16

"

12

"

Figure 2: Space requirements for the quick-release

front vise.

Figure 1: The Veritas

®

Quick-Release Front Vise mechanism, shown upside down.

*Main screw cover (not shown) located under main screw.

2

Veritas

®

Quick-Release Front Vise

Back Plate

Half Nut

Bushing

Base Casting

Main Screw*

Jaw Mounting

Screws

Handle

End Cap

Quick-Release Shaft

Half Nut Cam

Guide Rod

Quick-Release

Spring

Spring Nut

Washer

O-Ring

Tee

Quick-Release Lever

Front Plate