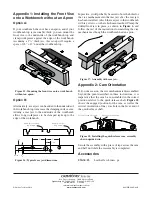

Appendix 1: Installing the Front Vise

onto a Workbench without an Apron

Option A:

If your workbench does not have an apron, and if your

workbench top is reasonably thick, you can mount the

front vise to the underside of the workbench top and

clamp workpieces against the edge of the workbench.

Assuming a 1

3

/

4

"

thick jaw, this set-up will require a

space of 18

"

× 12

"

under the workbench top.

Figure 15: Mounting the front vise onto a workbench

without an apron.

Option B:

Alternatively, a rear jaw can be added to the underside of

the workbench top to increase the clamping surface area.

Adding a rear jaw to the underside of the workbench

allows long workpieces to be clamped right up to the

edge of the workbench.

Notches to clear

dog holes.

Holes for mounting

lag screws.

1

1

/

8

"

3

/

4

"

5

"

5

"

1

11

/

16

"

1

25

/

32

"

Figure 16: Typical rear jaw dimensions.

In practice, it will probably be easier to bore the holes for

the vise mechanism into the rear jaw

after

the rear jaw

has been installed. Attach the rear jaw to the workbench

with lag screws, or other attachment method. Clamp the

drilled front jaw in place, as shown in

Figure 6

, and

follow the rest of the instructions for installing the vise

mechanism as though the workbench had an apron.

Figure 17: Assembly with rear jaw.

Appendix 2: Cam Orientation

If, for some reason, the vise mechanism is disassembled

beyond the point described in these instructions, it is

imperative that the cam be re-assembled in the correct

position relative to the quick-release shaft.

Figure 18

shows the engaged position for the cam, as well as the

critical orientation of the cross hole in the lever end of

the quick-release shaft.

Vertical Cross Hole Axis

Note cam orientation.

Figure 18: Installing the quick-release cam, assembly

shown upside down.

Secure the assembly with a piece of tape across the cam

and half nut while the reassembly is completed.

Accessories

05G34.03

Leather Jaw Liners, pr.

814 Proctor Avenue

Ogdensburg NY 13669-2205

United States

1090 Morrison Drive

Ottawa ON K2H 1C2

Canada

[email protected]

© Veritas Tools Inc. 2013

www.veritastools.com

843 IWE-449 Rev. B