Lower Calibration Temperature Adjustment:

From your previous calculations enter the lower mid melt temperature

calculated into the 'Low Temperature Value' box e.g. 1060 °C.

Enter the lower calibration temperature correction factor into the 'Low

Temperature Offset Box' e.g. 3.

Once saved the correction value will now be 1060 + 3 = 1063

Upper Calibration Temperature Adjustment:

From your previous calculations enter the upper mid melt temperature

calculated into the 'Low Temperature Value' box e.g. 1559 °C.

Enter the lower calibration temperature correction factor into the 'Low

Temperature Offset Box' e.g. -5

Once saved the correction value will now be 1559-5 = 1554

Save Settings

To save the calibration settings the save button must first be activated by

entering a password of 525 in the password box. The word 'Activated' will be

displayed if the correct password is entered and the save button will be

highlighted. Select the save button to save the settings.

The offsets can be reset to zero by selecting the 'Reset Offset' button.

Note

: This will only be activated if an offset value is present.

l

Following adjustment of the instrument the furnace must be re-tested starting from

section 5.6 to prove the results.

54

Содержание CARBOLITE GERO CAF G5

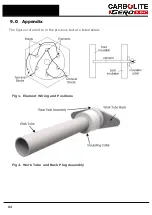

Страница 63: ...Fig 3 Front Tube Seal Assembly Fig 4 Door Arm Assembly 63 ...

Страница 64: ...Fig 5a Camera Mounting Bracket Fig 5b Lens and Camera Assembly 64 ...

Страница 65: ...Fig 5c Sliding the Camera Mounting Bracket Assembly onto the Door Arm 65 ...

Страница 66: ...Fig 5d Securing the Camera Mounting Bracket Assembly to the Door Arm 66 ...

Страница 67: ...Fig 5e Mounting the Lens and Camera Assembly 67 ...

Страница 68: ...Fig 5f Lens and Camera Assembly in Position 68 ...

Страница 69: ...Fig 6a Rear View of the Standard CAF G5 Furnace Showing Brick Box Assembly 69 ...

Страница 70: ...Fig 6b Rear View of the CAF G5 Biomass Furnace with Rear Illumination Showing Brick Box Assembly 70 ...

Страница 71: ...Fig 7 Front Tube Seal Position 71 ...

Страница 72: ...Fig 8 Tube End Seal Assembly Tightening Sequence Fig 9 Work Tube Front Support 72 ...

Страница 73: ...Fig 10 Fitting the Door Arm Assembly Fig 10a Adjusting the Door Arm Assembly 73 ...

Страница 74: ...Fig 11a Furnace Case and Controls 74 ...

Страница 75: ...Fig 11b Gas Inlet Pipe Fig 12 Positioning the Furnace 75 ...

Страница 76: ...Fig 13a Positioning Samples on the Sample Carrier Fig 13b Loading Samples into the Mouth of the Work Tube 76 ...

Страница 77: ...Fig 13c Loading Samples into the Work Tube 77 ...

Страница 78: ...Fig 16 File Folder 78 ...

Страница 79: ...Fig 17 Door Arm Assembly Exploded View 79 ...

Страница 82: ...SST DT HT FT Fig 18 Report Sheet Page 2 Side View Plan View Fig 19 Formed Wire Sample 82 ...

Страница 83: ...Fig 20 Sample Carrier Sample Tiles and Sample Positions 83 ...

Страница 84: ...Fig 21a Coal and Coke Test Piece Mould Fig 21b Biomass Test Piece Mould and Hand Press 84 ...

Страница 85: ...Fig 22 Sample Loading Tool Fig 23 Camera Ethernet Connection 85 ...

Страница 86: ...Fig 24 LED Driver Connection 86 ...

Страница 87: ...Notes Service Record Engineer Name Date Record of Work ...