44

VaporTEK Calibration

Refer to dispenser manufacturer’s manual for VaporTEK system commissioning before

conducting the A/L calibration procedure.

Manual Calibration Using The Speed Setup If High Voltage Signals M1 And M2

Are Used

Check the dispenser flow rate during a real transaction on the highest nozzle clip. Setup the speed to M1 or M2 in

order to achieve the same vapor flow rate (A/L = 100%) using the sub item “2. Set config”.

Dry Calibration - A/L Adjustment

A/L adjustment using automatic dry calibration can be performed only with the VaporTEK Plus or VaporTEK Ultra

configurations.

Equipment Required

• FB1 hand held terminal with 15-pin to RS422 cable

• Gas meter

• A/L nozzle adapter (varies by nozzle manufacturer)

• Hoses

Initial Setup

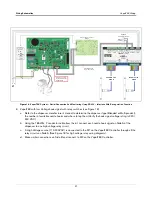

1.

Verify power is available at the VaporTEK-3 Controller board, both the V1 and V6 red LED’s are on and the V3

green LED is flashing slowly.

New Connection Hyperterminal

File Edit View Call Transfer Help

Print echo

Capture

NUM

CAPS

SCROLL

9600-8-N-1

Auto detect

Connected 0:02:44

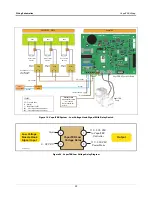

2. Set Config

-------------

Pump Motor Type: VaporTEK

VTEK-RS422 Type: Slave Device

HV Nozzle Speed: M1 = 2500 rpm

HV Nozzle Speed: M2 = 2500 rpm

Set M1 - Input performance (0...250rpm x10):100

Set M2 - Input performance (0...250rpm x10):100

Do you want to save it?[Y/N]: y

Config has been stored successfully

Pump Motor Type: VaporTEK

VTEK-RS422 Type: Slave Device

HV Nozzle Speed: M1 = 1000 rpm

HV Nozzle Speed: M2 = 1000 rpm