16

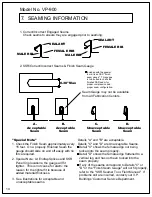

Check the seam width often with the provided seam gage. If the seam gage will not fit on the

seam, stop immediately and adjust the seamer tool. Under normal circumstances, the seamer tool

should require only adjustment of Station #3. If the seam is significantly wider than the seam gage

or the seam is not properly formed, all stations may require attention. Both adjustments will be

described below.

Model No. VP-900

9. SEAMER ADJUSTMENT

CHECKING THE SEAM WIDTH

STATION #3 ONLY ADJUSTMENT

ALL STATION ADJUSTMENT

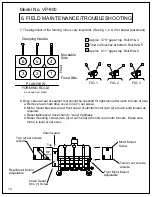

Set the feeler gage up for a gap setting of 0.075".

Place the feeler gage between rollers #1 and #4. These are the first two rollers from the front

of the machine.

Clamp the handle down. The gage should be snug between the two rollers. If it is not follow

the procedure previously listed to adjust the gap.

Repeat using the same 0.075" gap for station two. This is the station with the fiber roller.

Finally adjust the feeler gage to 0.110" and perform the same operation with the third station.

This should place the machine back into the proper setup for seaming.

Run a small length of test seam and check with the seam gage. If the seam is wide, adjust

only station #3. This is the station at the rear of the machine.

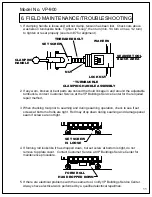

Begin by loosening the set screw on the turnbuckle as shown in the diagram. Due to

differences in seamer tool turnbuckles, no all turnbuckles will be equipped with a set screw.

This is no cause for alarm.

Once it has been determined the set screw is loose or that the turnbuckle is not equipped with

a set screw, remove the bolt that holds the turnbuckle onto the clamping handle. The

turnbuckle can then be pivoted free of the clamping handle.

Rotate the turnbuckle, 1/2 turn counter clockwise to tighten the seam. A 1/2 counterclockwise

rotation of the turnbuckle will tighten the seam approximately 0.015".

Replace the turnbuckle back on the clamping handle. Replace the bolt in the turnbuckle and

tighten the set screw, if equipped.

Place the seamer back on the seam and run a test section. Check the seam with the seam

gage. If the seam is still too wide repeat the procedure until the seam gage will fit properly on

the seam.

For minor adjustments to the tool to reduce seam width, perform this procedure only on station

number three.

If the seam is extremely wide or if the seam is not forming properly, perform the following procedure

using a feeler gage.

1.

2.

3.

4.

5.

1.

3.

4.

2.

5.

6.

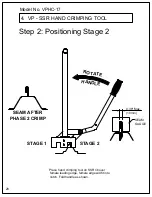

Содержание SSR 900

Страница 2: ......

Страница 20: ...Model No VPHC 17 17 1 VP SSR HAND CRIMPING TOOL...