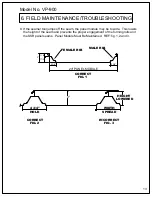

1. Correct/Incorrect Engaged Seams

Check seams to ensure they are engaged prior to seaming.

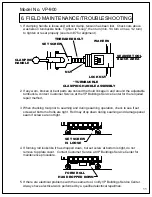

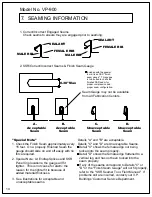

2. SSR/Correct/Incorrect Seams & Finish Seam Gauge

0.38" Max

Included with the seamer

tool kit is an SSR "finish

seam gauge". This guage

is to be used to check the

finished SSR seam for

proper compression and

proper seam configuration.

A.

Acceptable

Seam

B.

Acceptable

Seam

C.

Unacceptable

Seam

D.

Unacceptable

Seam

Seam Gauge may not be available

from all Fabrication Centers.

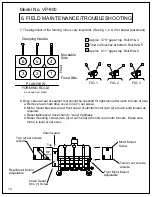

SEALANT

SEALANT

FEMALE RIB

MALE RIB

MALE RIB

"Special Note"

1. Check the Finish Seam approximately every

15 feet. On a properly Finished Seam the

gauge should slide on and off easily with no

force required.

2. Special Note: At Endlap Splices and SSR

Panel Clip locations, the gauge will fit

tighter. This is not cause for alarm; the

reason for the tighter fit is because of

added material thickness.

3. See illustrations for acceptable and

unacceptable seams.

Details "A" and "B" are acceptable.

Details "C" and "D" are Unacceptable Seams.

Detail "C" shows the female edge not being

tucked into the seam properly.

Detail "D" shows the female edge flattened to a

vertical leg and has not been tucked into the

seam properly.

If any of the seams correspond to Details "C" or

"D" or the "Finish Seam Gauge" will not fit properly,

refer to the "SSR Seamer Tool, Field Manual." If

problems still are incurred, contact your V.P.

Buildings' Customer Service Department.

FEMALE RIB

Model No. VP-900

14

7. SEAMING INFORMATION

Содержание SSR 900

Страница 2: ......

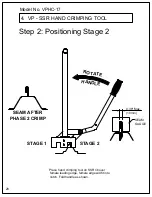

Страница 20: ...Model No VPHC 17 17 1 VP SSR HAND CRIMPING TOOL...