6

5

4

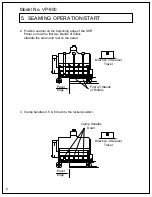

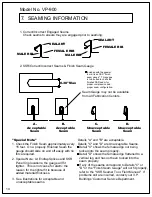

0.38" Max

PROPER SEAM PROFILE

AFTER SEAMING

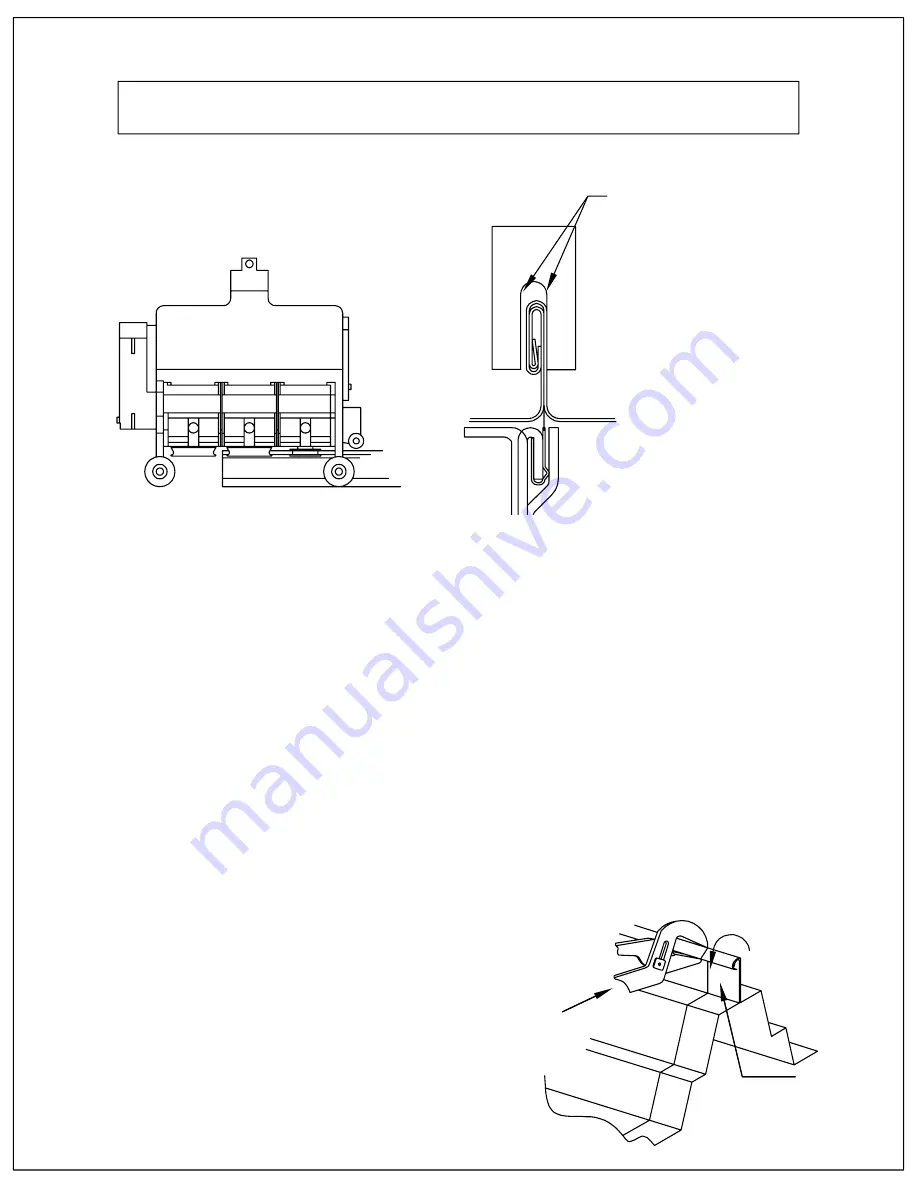

4. Turn Power Switch on and run seamer about 4 inches.

Check seam to ensure proper seaming operation.

5. After seam is checked and proper operation is verified,

continue to seam remainder of panel, inspecting seam

continuously. Seamer should travel approximately 25 feet

per minute.

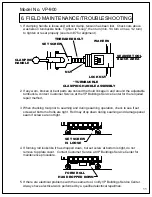

6. When the seamer tool approaches the end lap, "STOP"

the seamer tool before crossing the End Lap and hand

crimp the leading edge of female lip. Also, it will slow

down due to the additional thickness of metal. This

heavier load requirement can be detrimental to the

seamer tool if it should come to a complete stall. The

operator should assist by manually pushing the seamer

forward by the handle until the seamer clears the lap.

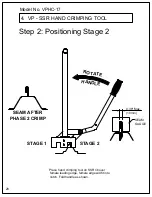

HAND CRIMPING AT START OF SEAMING OPERATION:

CRIMPING THE FEMALE LIP OF SEAM INTO POSITION.

7. When approaching the end of the panel, use extreme

caution, and stop seamer while rear wheels remain on

panel. Roll machine back to a safe working area.

Preform/hand

crimp approx. 1" female lip

TUCK LIP

CHANNEL LOCKS

Model No. VP-900

CAUTION:

9

5. SEAMING OPERATION/START

Содержание SSR 900

Страница 2: ......

Страница 20: ...Model No VPHC 17 17 1 VP SSR HAND CRIMPING TOOL...