6

MIN

MAX

1

2

3

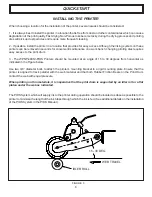

Use two 3/8” diameter bolts to attach the printer’s mounting bracket to a rigid mounting plate. Ensure that the

printer is aligned to track parallel with the web material and that both Rubber Friction Bears on the Print Drum

contact the web with equal pressure.

When printing on thin materials, it is imperative that the print drum is supported by an idler roll or a flat

platen under the web as indicated.

The PIDS System which will supply ink to the printer during operation should be located as close as possible to the

printer to minimize the length of the ink tubes through which the ink is fed. (See additional details on the installation

of the PIDS System in the PIDS Manual.)

WEB TRAVEL

INSTALLING THE PRINTER

When choosing a location for the installation of the printer, several issues should be considered:

1 - It is always best to install the printer in a location that is free from dust and other contaminates which can cause

degradation of the print quality. Fast drying Non-Porous Inks become tacky during the drying process and printing

dies will pick up dust particles and require more frequent cleaning.

2 - If possible, install the printer in a location that provides for easy access. Although the inking system on these

printers can be removed in seconds for convenient maintenance on a work bench, changing printing dies requires

easy access to the print drum.

3 - The WPNP-400NI-PIDS Printers should be mounted at an angle of 15 to 30 degrees from horizontal as

indicated in the Figure below.

IDLER ROLL

FIGURE 3

15 - 30 DEG.

QUICK START

Содержание WPNP-400NI-PIDS

Страница 26: ...26 ...