15

BASIC PRINCIPLES OF OPERATION

FIGURE 33

THE PIDS SYSTEM

The positive displacement peristaltic pump heads used in the PIDS systems move ink through progressive waves

of contraction and relaxation of a resilient pump tube. The ink never touches any of the pumps component parts

so maintenance is limited to replacing the pump tube after approximately 1,000 hours of operation. Universal’s

quick disconnect replacement pump tube assembly, facilitates pump tube changes in less than 10 seconds.

Universal’s Programmable Ink Delivery Systems were developed as an advanced method of supplying ink “on-

demand” to contact roll printing equipment. The PIDS system combines the simplicity of electronic programming

and the accuracy of peristaltic metering pumps to automatically deliver precise amounts of ink to the printers at

prescribed intervals.

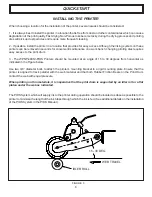

The PIDS system works with the Non-Porous Web printers through a

unique wiper adapter as shown. Ink from the PIDS System is injected

through a pair of miniature duck bill check valves between two very thin

plastic membrane wipers which rest against the face of the ink roll. The

wipers transform the ink into a very thin film which is then evenly spread

across the entire face of the roll. This design provides instantaneous

printer response, ensures uniform print density over the full print width of

the printer .

It is very important to note that when web velocities exceed 400 FPM, having a large volume of ink in the printer’s

ink roll can cause inking system leakage problems. The higher RPM of the ink roll at these web velocities will

cause ink to rise to the surface of the ink roll and can result in ink being thrown off the surface of the roll and into

the inking system housing. To avoid this potential problem in high speed printing applications, the ink roll should

initially be thoroughly saturated to prepare it for use and then most of the ink should be removed from the roll prior

to installation. This process wets all the cells in the foam and dramatically increases the rate of ink absorption

when it is delivered by the PIDS-DIGITAL-CE System. It is important to understand that the ink required for

printing will be delivered by the PIDS System as needed so having a large volume of ink in the ink roll is unnecessary

and undesirable.

PIDS-DIGITAL-CE PROGRAMMABLE INK DELIVERY SYSTEMS

The PIDS-DIGITAL-CE Programmable Ink Delivery Systems require constant data input from a low resolution

encoder in order to monitor web motion and velocity. To eliminate the need to install a separate friction driven

encoder on the moving web, it was determined that the most efficient way to provide this data, without complicating

the installation, was to modify the friction driven printers which allows them to serve a dual purpose.

The details of this modification are provided on the following pages.

IMPORTANT NOTE FOR HIGH SPEED PRINTING APPLICATIONS

Содержание WPNP-400NI-PIDS

Страница 26: ...26 ...