GENERAL

Temperature variations are sensed by the liquid

filled bulb which hydraulically transmits motion

through a mechanism which rotates the indicating

pointer and actuates precision snap-acting

switch(es). Controller settings are made by

turning the adjustment knob(s). Thermometer

types T800 (with enclosure) and T800S

(skeleton) provide temperature indication only

with no control switches.

Tools Needed

Screwdriver to secure

customer supplied screws

Screwdriver

5/64” Allen Wrench

INSTALL UNIT WHERE SHOCK, VIBRA-

TION AND TEMPERATURE FLUCTUA-

TIONS ARE MINIMAL. ORIENT UNIT SO THAT

MOISTURE IS PREVENTED FROM ENTERING

THE ENCLOSURE. IT IS IMPERATIVE THAT

PROPERLY RATED EXPLOSION-PROOF SEAL-

ING FITTINGS BE USED FOR ELECTRICAL

WIRE ENTRY OR 820E AND 822E TYPE UNITS.

DO NOT MOUNT UNIT IN AMBIENT TEMPERA-

TURES EXCEEDING PUBLISHED LIMITS.

PREVENTATIVE MAINTENANCE / PERIODIC

TESTING (6 MONTHS OR SOONER AS DIC-

TATED BY THE ENVIRONMENT) IS NECESSARY

TO ENSURE OPERATION OF THE PRODUCT TO

SPECIFICATION. LUBRICATE ALL PIVOT POINTS

AND MOVING PARTS, TO PREVENT CORROSION,

WITH COMPATIBLE DRY LUBRICANTS OR LIGHT

GREASE.

DO NOT KNOCKOUT ANY PLUGS ON

EXPLOSION-PROOF TYPES 820E OR 822E

When mounting 800 or 802 type controls, it may be

necessary to remove adjustment knob and front cover.

The knob is secured with a 5/64” Allen Setscrew. The

cover is secured by four screws at the corners.

MOUNTING

The controller may be mounted in any position to

either a surface or panel (1/4” thick maximum).

Locate it where vibration, shock and ambient

temperature fluctuations are minimal. It is recom-

mended that mounting the unit with the conduit

connection on the top be avoided.

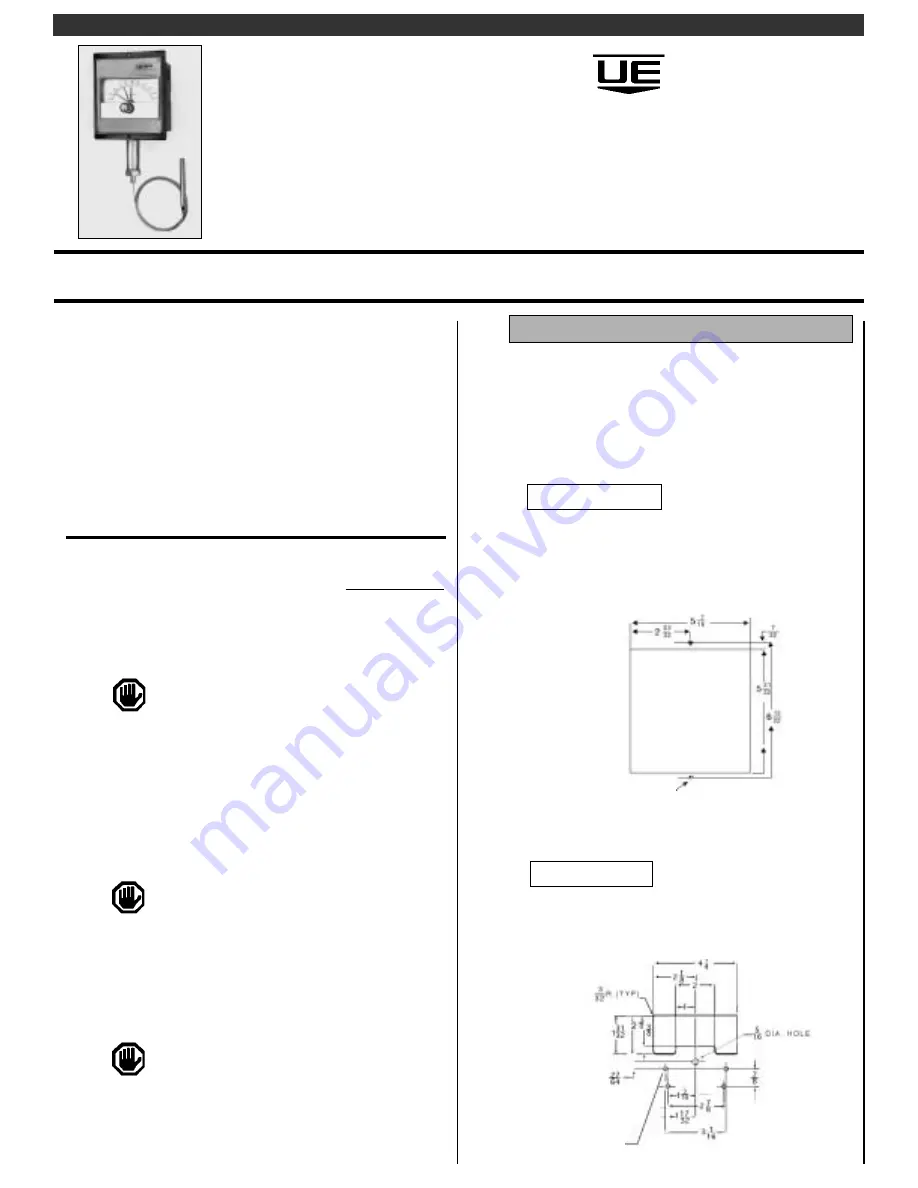

To Flush Mount

(Not applicable to explosion-proof types)

Cut out the panel as shown in Figure 1A. Mount

to the panel using the two holes located on the

flange of the enclosure.

To Panel Mount

(Skeletons)

Prepare the cut out, drilling the holes for the knob

shaft and the mounting holes per Figure 1B.

U N I T E D E L E C T R I C

C O N T R O L S

Installation and Maintenance

Instructions

IM800-03

Please read all instructional literature carefully and thoroughly before starting. Refer to the final page for the listing of

Recommended Practices, Liabilities and Warranties.

800 Series

Temperature Controllers and

Thermometers

Types 800, 800S, T800, T800S, 802,

802S, 802P, 802PS, 820E*, 822E*

*Explosion-Proof Class I, Groups B, C, D;

Class II, Groups E, F & G; Class III

Part I - Installation

Figure 1A - Flush Mounting

Figure 1B - Panel Mounting (Skeleton)

Clearance for #6 screw

(4) places (3/16 Max.

Panel Thickness)

Clearance for #8 screw - (2) places

Содержание 800

Страница 7: ...Dimensions 800 Series 820E 822E ...