-

6

-

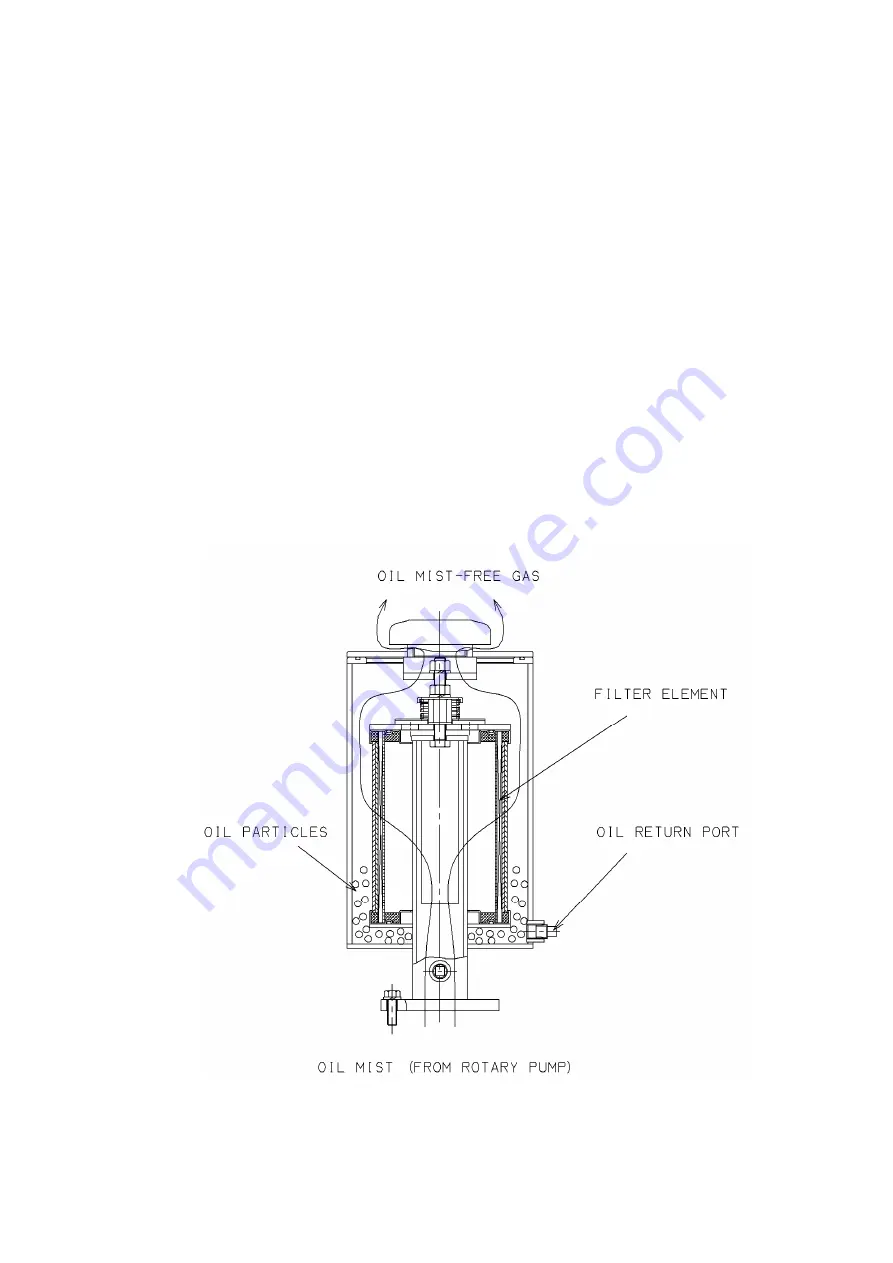

2.4 Structure

(1) Gas (air, nitrogen, etc.) exhausted from an oil sealed rotary vacuum pump blows up the oil inside

and enters an oil mist trap along with particles of misted oil. These fine oil particles (oil mist) get

trapped when going through a filter element.

Rather large aggregated oil particles are collected between the main body of the oil mist trap and

the filter element, and get exhausted from an oil returning port. Most of the oil mist will be

removed before the gas comes out from the outlet.

(2) This unit has a pressure-releasing device.

Clogging of a filter element may cause hazardous pressure rise at start-up or during evacuation of

a vacuum chamber. A pressure-releasing device, which opens a mechanical valve to release

internal pressure when it reaches 0.04MPa (0.4kg/cm

2

) (gauge pressure), is a standard

equipment. With this device, internal pressure will never rise too rapidly.

(Note) When starting a pump, especially when the oil temperature is low, the pressure- releasing

device which functions for a moment to meet the temporary rise of internal pressure may let

out a little smoke. Nevertheless, it is not attributed to filter element clogging.

Fig.3 Structures