U-Line Electrical / Plumbing Specfications

14

To connect to drain:

WARNING

To prevent accidental electrocution, make certain that

the floor surfaces surrounding the unit are dry

whenever power is removed from, or applied to, the

unit.

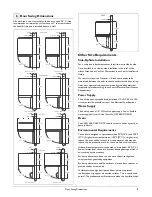

1. Slide 2 hose clamps onto the drain

connection on the rear of the

appliance.

2. Insert the barbed fitting halfway

into this connection.

3. On the other end of this barbed

fitting attach the 5/8” braided

tubing.

4. Slide a clamp on each side of the

barbed fitting as shown (see Figure

45).

5. Insulate the drain line, if necessary

to prevent condensation.

Locally-Installed Drain Pump

If a gravity drain connection is not possible, and you have not

purchased a CLR2160 or CLRCO2175 with factory-installed

pump, we strongly recommend the use of the U-Line P60 drain

pump. The U-Line P60 drain pump is available through your Dealer,

with complete installation instructions. If a pump other than the U-

Line P60 drain pump is to be used, it must meet the following

specifications:

• It must be UL listed and have a UL listed, 120 VAC, 3-wire

grounded power cord.

• It must have overall maximum outside dimensions of 8-3/4"

wide x 5-3/4" deep x 7-3/4" high.

• It must have a minimum flow rate of 1.5 gallons per minute at

10 feet of lift.

• It must have a sealed sump which does not allow water leakage

in the case of a power outage, restricted drain or pump failure.

• It must have a check valve in the discharge line to prevent waste

water return to the pump.

• It must have an overflow protection control which will shut off

power to the ice maker in the event of a pump failure.

• It must have an operating temperature range of 50°F to 110°F

(10°C to 40°C).

IMPORTANT

IMPORTANT

In the event of a power outage, restricted drain or pump

failure, the failure to use the U-Line P60 drain pump or a

pump with the above listed specifications, could result in

substantial water leakage and pooling with severe and

costly water damage and related consequential damages

and harm.

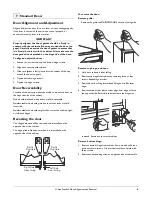

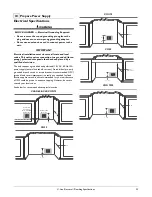

Final Water Connection:

1. Connect the water supply fitting by screwing the brass garden

hose fitting to the water valve in the rear of the unit.

2. Tighten this fitting with pliers.

IMPORTANT

IMPORTANT

Do not use Teflon tape or joint compound on this fitting.

The rubber washer provides an adequate seal. Other

materials could cause blockage of the valve.

3. Attach the copper water line to the back of the unit using the

supplied clamp and the back panel screw (see above). This will

prevent rotation of the line when moving the unit.

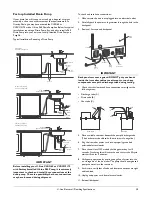

4. Plug in the unit and put unit into OFF mode by holding the

power key for 10 seconds. Not doing this will cause the unit to

fill with water for 3 minutes.

5. Turn on the water supply and ensure the connections are free of

leaks.

6. Begin to push the appliance into the desired cabinet opening.

The copper tubing should remain in 2 coils behind the unit.

IMPORTANT

IMPORTANT

Normal operation creates some vibration. A water supply

line contacting cabinet wall may cause excessive noise

during operation or damage to the line.

7. While pushing the unit into the opening, continuously reroute

the drain tube (if installed) to avoid kinks. The most common

installation pulls the slack into an adjacent cabinet or basement

area.

Drain Fitting from

Back of Unit

Worm Clamps

Drain Line

5/8" x 5/8"

Barb Connector

ULIN_S_0166b2_A