U-Line Electrical / Plumbing Specfications

13

Factory-Installed Drain Pump

If your drain line will run up to a stand pipe, disposal or spigot

assembly, or does not otherwise meet the requirements for a

Gravity Drain, you may have ordered the CLR2160 or

CLRCO2175 with a U-Line P60 Drain Pump. See Below for typical

installations requiring a Drain Pump. If you need to install a P60

Drain Pump into your unit, see Locally-Installed Drain Pump on

Page

14

.

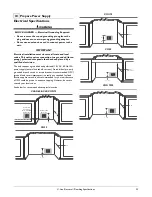

Typical Installations Requiring a Drain Pump

IMPORTANT

IMPORTANT

Before installing your U-Line CLR2160 or CLRCO2175

with Factory-Installed U-Line P60 Pump, it is extremely

important to check and test all hose connections at the

drain pump. There is a possibility that hose connections

may have loosened during shipment.

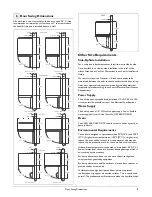

To check and test hose connections:

1. Make certain the unit is not plugged into an electrical outlet.

2. Carefully push the power cord grommet through the hole in the

back panel.

3. Remove 12 screws and back panel.

IMPORTANT

IMPORTANT

Back panel serves as a guard. DO NOT put your hands

inside the ice maker cabinet or attempt to touch any

components except the discharge tube during testing.

4. Check that the clamps and hose connections are tight at the

following areas:

• Discharge tube (A)

• Drain tube (B)

• Vent tube (C)

5. Place a suitable container beneath the pump’s discharge tube.

(The bucket must be able to hold a minimum of one gallon.)

6. Plug the ice maker power cord into a properly grounded,

polarized electrical outlet.

7. Place the unit into OFF mode by holding power key for 10

seconds. Not doing this will cause the unit to start the fill cycle

which will run for 3 minutes.

8. Verify pump operation by pouring one gallon of water into the

ice storage bin of the ice maker. The pump should energize and

pump the water into the container.

9. At this time, verify that all tube and clamp connections are tight

and leak-free.

10. Unplug unit power cord from electrical outlet.

11. Reinstall back panel.

Cold

Water

Hot

Water

Waste

Waste

Shut-Off

Valve

Stand Pipe

P60 Pump Required

Air Gap

(Optional Hook-Up)

Cold

Water

Hot

Water

Waste

Shut-Off

Valve

Disposal Assembly

P60 Pump Required

Waste

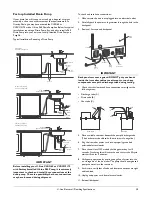

Cold

Water

Shut-Off

Valve

Hot

Water

Air Gap

(Optional Hook-Up)

Y-Branch Tailpiece

P60 Pump Required

Power

Cord

Grommet

Drain

Fitting

Back

Panel

Water

Connection

Screws

Back View

Side View

B

B

A

C

C