Operation

g027327

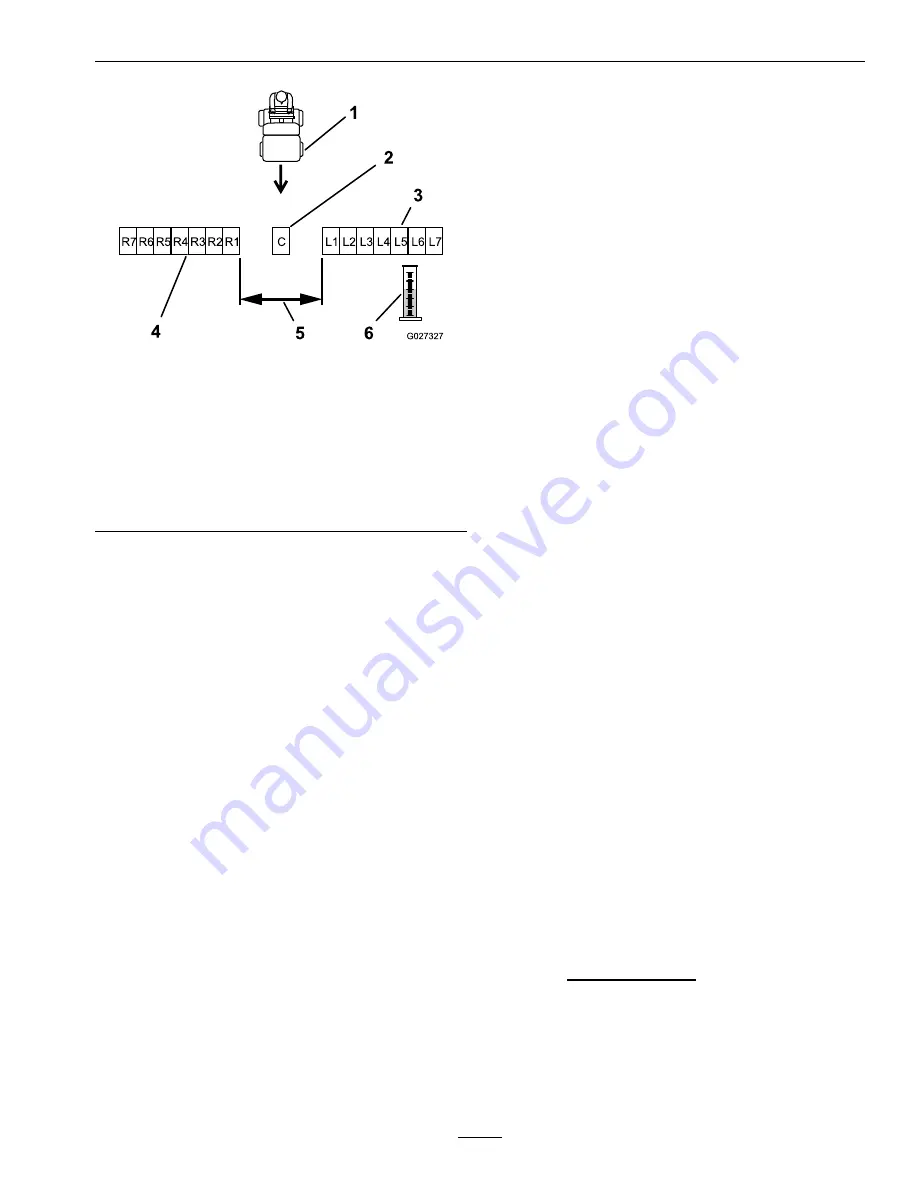

Figure 31

1.

Spreader moving

towards pans

4.

Right collection pans (no

gap between each)

2.

Center collection pan

5.

L1 and R1 collection

pan gap (spread apart to

allow machine to pass

through)

3.

Left collection pans (no

gap between each)

6.

Graduated measuring

cylinder

4.

Reference the

Spreading Charts

section to

determine the appropriate rate dial setting (see

Figure 13).

5.

Fill the hopper approximately half-full with the

desired material.

6.

Set the impeller speed to the appropriate

broadcasting rate.

7.

Pull the granular gate control to the open position

and drive the spreader, at the appropriate speed,

over the center pan. Repeat this several times,

moving in the same direction each time, until

enough material is dispensed to fill the center

graduated measuring cylinder half full.

8.

Label each graduated measuring cylinder to

correspond with the distribution pans (i.e. ...L2,

L1, Center, R1, R2....) (reference Figure 30 and

Figure 31).

9.

One at a time, take a collection pan and dump

the contents into the corresponding graduated

measuring cylinder. Record the amount of

material collected and return the pan to its

location. Repeat this until all pan contents have

been emptied.

10.

With the graduated measuring cylinder in the

same straight line as the pans, evaluate the volume

of material in each cylinder to determine the

quality of the distribution from the spreader.

11.

To adjust the spreader pattern, refer to the

Spreader Pattern Adjustment

section.

12.

Repeat steps 5 through 11 until an uniform

pattern is achieved.

Determining the Effective Spreading

Width

The effective width is used to determine the uniform

distribution of the material.

Note:

The spreading width range is 3 ft (0.9 m) up

to 25 ft (7.6 m).

1.

After the spreader pattern is correctly adjusted,

evaluate the amount of material in the center

graduated measuring cylinder.

2.

Locate the two tubes, one each side of center, that

contain 1/2 the measured amount of the material

that you observed in the center graduated cylinder.

3.

Go to the two corresponding pans. Starting from

the outer edge, measure and record the distance

between left pan, through the center pan, to the

outer edge of the right pan.

Note:

This measurement is the effective

spreading width.

Calculating the Application Rate

1.

Determine the amount of product to be applied.

2.

Determine the calibration course

A.

Determine the amount of product to be spread

per 1,000 ft

2

(93 m

2

). Use the recommended

rate from the

Spreading Charts

section or

the product manufacturer’s label as a guide.

B.

Determine a course length by dividing 1,000

ft

2

(93 m

2

) by the effective spread width.

For example, if the effective width is 6 feet

(1.8 meters), then the calibration course length

equals 167 ft (51 m).

Course Length

1,000 ft

2

(93 m

2

)

6 ft (1.8 m)

=

167 ft (51 m)

C.

The calibration course is 6 ft (1.8 m) by 167

ft (51 m).

D.

Measure and visibly mark the course length.

Make sure to allow ample distance before the

35